Introduction:

HUADA LIFT THIN WIRE MACHINE

Price:

+8619859567581

Wire diameter 0.45-0.65mm: material yield rate exceeds 97%

Increases efficiency 1.5-2 times that of conventional cutting, and cancut hard stones;

No vibration, low noise

A wide range of cutting sizes, the thickness range of the cutting slab is 5-30mm

Stone waste is reduced by more than 80%.

|

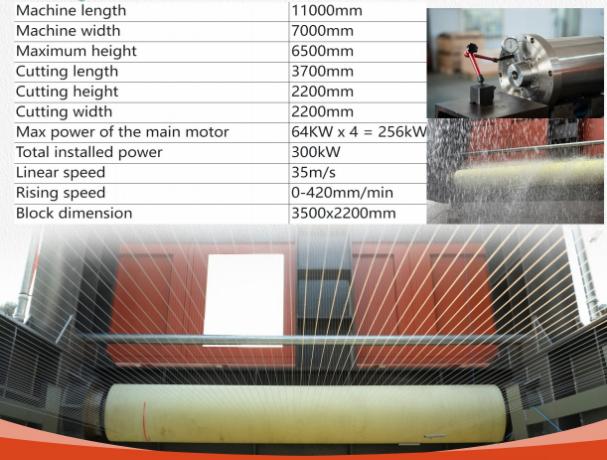

Machine length |

11000mm |

|

Machine width |

7000mm |

|

Maximum height |

6500mm |

|

Cutting length |

3700mm |

|

Cutting height |

2200mm |

|

Cutting width |

2200mm |

|

Max power of the main motor |

64KWx4=256kW |

|

Total installed power |

300kW |

|

Linear speed |

35m/s |

|

Rising speed |

0-420mm/min |

|

Block dimension |

3500x2200mm |

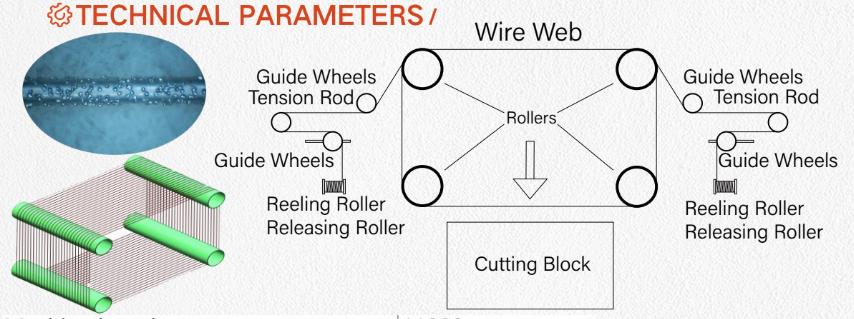

The stone industry relies heavily on efficient cutting machines to process various materials, and wire saw machines are a popular choice for steel cutting. These machines offer numerous...

Wire diameter 0.45-0.65mm: material yield rate exceeds 97% Increases efficiency 1.5-2 times that of conventional cutting, and cancut hard stones; No vibration, low noise A wide range...

Features : An advance type of dws equipped with permanet magnet Technology offering additional features for quarrying all types of stones: Eco-friendly and up to 30% more efficient th...

The Satisfaction Of Our Customers Is Our Motivation!

Learn more about stone cutting machine!

10

2025-07

26

2025-01

25

2025-01

24

2025-01

23

2025-01

Please Fill In The Correct Tel & E-mail,

We'll Contact You As Soon As Possible!