Author:Huada Quarrying Machine FROM:Stone quarry machine manufacturer TIME:2025-01-26

The quarrying industry relies heavily on advanced machinery to extract stone and minerals efficiently and safely. Among these vital tools, the mine wire saw cutting machine stands out for its precision and effectiveness. This innovative device has revolutionized the way stone is cut, offering numerous advantages over traditional methods. In this article, we will explore the significance of mine wire saw cutting machines in quarrying, their benefits, applications, and the future of this technology.

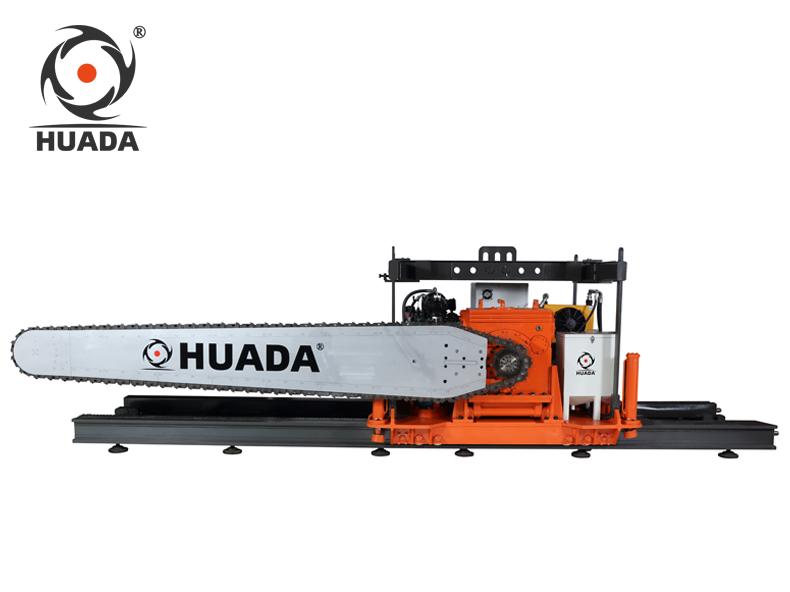

Mine wire saw cutting machines utilize a continuous loop of wire with diamond segments attached to cut through hard materials such as granite, marble, and other stones. Unlike conventional saws that use blades, the wire saw employs a flexible wire that enables it to navigate complex shapes and angles. This flexibility not only enhances the quality of the cut but also minimizes waste, making it an essential tool for quarry operators looking to maximize their output.

One of the primary advantages of mine wire saw cutting machines is their ability to produce precise cuts with minimal kerf loss. Traditional cutting methods often result in significant waste due to the thickness of the blades, whereas wire saws have a much thinner profile, allowing for more efficient material usage. Moreover, the smooth finish achieved by wire saws reduces the need for additional processing, saving both time and resources.

Mine wire saw cutting machines are incredibly versatile, suitable for various applications beyond simply cutting raw blocks from quarries. They can be employed in intricate tasks such as contour cutting, which involves shaping stone into specific designs for architectural purposes. Additionally, wire saws can be used in the production of tiles and slabs, further diversifying their role in the stone industry. This versatility makes them indispensable in modern quarrying operations.

Safety is a paramount concern in the quarrying industry, and mine wire saw cutting machines contribute to a safer working environment. Their design minimizes the risk of accidents associated with traditional cutting methods, such as kickbacks and blade breakage. Furthermore, these machines often come equipped with advanced safety features, including automatic shut-off mechanisms and protective enclosures, ensuring operators are safeguarded during operation. This focus on safety not only protects workers but also enhances overall operational efficiency.

In an era where environmental sustainability is critical, mine wire saw cutting machines present a more eco-friendly alternative to conventional cutting methods. The reduced waste generated during the cutting process directly translates to less environmental impact. Additionally, many modern wire saws are designed to operate with lower energy consumption, further contributing to sustainability efforts within the industry. By adopting these technologies, quarry operators can align their practices with global environmental standards.

The future of mine wire saw cutting machines looks promising, with ongoing advancements in technology. Manufacturers are continuously innovating to enhance the efficiency and performance of these machines. For instance, the integration of artificial intelligence and automation is expected to improve operational control and reduce human error significantly. As these technologies evolve, quarry operators can anticipate even greater efficiencies and lower costs, solidifying the wire saw’s position as a cornerstone of the quarrying industry.

In conclusion, mine wire saw cutting machines are essential tools in the quarrying sector, offering unmatched precision, versatility, and safety. Their ability to enhance operational efficiency while minimizing waste aligns perfectly with the industry's growing emphasis on sustainability. As technology continues to advance, the role of wire saws will likely expand further, ensuring they remain integral to the future of quarrying. Embracing these innovations will not only benefit individual operations but also contribute to a more sustainable and efficient industry overall.