Author:Huada Quarrying Machine FROM:Stone quarry machine manufacturer TIME:2025-01-24

Stone chain saw machines have become an essential tool in the stone industry, revolutionizing the way stone is extracted and processed. These machines are designed to cut through hard materials such as granite, marble, and limestone with precision and efficiency. As the demand for stone products continues to rise, understanding the different types of stone chain saw machines available in the market is crucial for both manufacturers and users. This article aims to explore the various kinds of stone chain saw machines, their features, applications, and benefits.

There are several types of stone chain saw machines, each designed for specific cutting tasks and materials. The most common types include:

Horizontal stone chain saw machines are designed to perform horizontal cuts in stone blocks. These machines are equipped with a powerful motor that drives a diamond chain, allowing for smooth and precise cuts. They are typically used in quarries for extracting large blocks of stone. The advantage of horizontal machines is their ability to handle thick materials without compromising cutting speed.

Vertical stone chain saw machines operate similarly to horizontal machines but are oriented vertically. This design allows for vertical cuts, which are essential for shaping stone blocks into slabs or tiles. Vertical machines are often used in processing plants where stone is refined into finished products. They provide high accuracy and can be adjusted for different thicknesses of stone.

Portable stone chain saw machines are lightweight and designed for mobility. These machines are ideal for small-scale projects or jobs that require cutting stone on-site. They are often used by stonemasons and contractors who need to work in various locations. Despite their size, portable machines offer impressive cutting capabilities and versatility.

CNC (Computer Numerical Control) stone chain saw machines represent the latest advancement in stone cutting technology. These machines are programmed using computer software to execute precise cuts and intricate designs. CNC machines are widely used in modern stone fabrication facilities for producing complex shapes and patterns, making them invaluable in architectural projects.

Diamond wire stone chain saw machines utilize a wire embedded with diamond segments to cut through stone. This technology allows for very fine cuts with minimal waste. These machines are particularly effective for cutting hard stones and are commonly used in quarries and large-scale stone processing operations. The flexibility of the wire allows for intricate designs and shapes that are difficult to achieve with traditional blades.

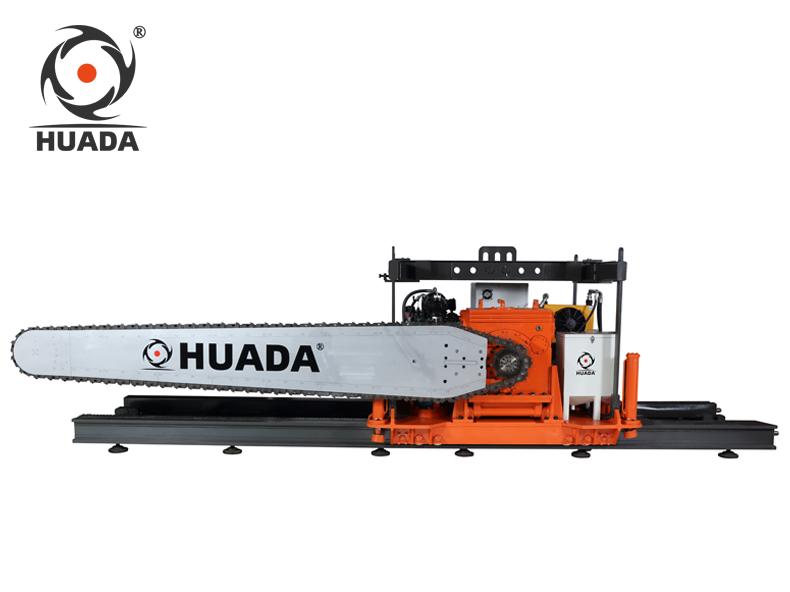

Hydraulic stone chain saw machines use hydraulic power to drive the cutting chain. This mechanism provides significant cutting force, making it suitable for tough materials. Hydraulic machines are often used in quarrying operations and can handle challenging cutting conditions. They are also known for their durability and longevity in demanding environments.

When selecting a stone chain saw machine, it's essential to consider several key features:

The cutting speed of a stone chain saw machine is a critical factor that influences productivity. High-speed machines can reduce cutting time, improving overall efficiency in stone processing. Users should choose machines that balance speed and precision for optimal results.

Stone chain saw machines can be powered by electricity, diesel, or hydraulics. The choice of power source depends on the application and location of use. For example, electric machines are suitable for indoor use, while diesel-powered machines are more appropriate for outdoor quarrying operations.

The material of the cutting blade significantly affects performance and longevity. Diamond blades are preferred for their durability and cutting efficiency, especially when working with hard stones. Users should ensure compatibility between the machine and the blade material for optimal cutting performance.

Stone chain saw machines have a broad range of applications across various industries:

In the quarrying industry, stone chain saw machines are essential for extracting raw stone blocks efficiently. Their ability to make precise cuts in tough materials reduces waste and increases yield, making them indispensable in modern quarrying operations.

After extraction, stone chain saw machines play a vital role in processing raw stone into finished products. They are used to cut slabs, tiles, and other shapes required in construction and decorative applications. Their versatility allows for customization and intricate designs.

In restoration and renovation projects, stone chain saw machines are used to match existing stonework. Their precision cutting capabilities enable artisans to replicate historical designs accurately, preserving the integrity of cultural heritage sites.

Stone chain saw machines have transformed the stone industry by providing efficient and precise cutting solutions. With various types available, each designed for specific applications, users can choose machines that best meet their needs. As technology continues to advance, the evolution of stone chain saw machines will likely lead to even greater efficiencies and capabilities, further enhancing the stone extraction and processing industries. Understanding these machines is crucial for anyone involved in stone-related work, enabling them to make informed decisions that improve productivity and quality.