Author:Huada Quarrying Machine FROM:Stone quarry machine manufacturer TIME:2025-01-25

Wire saw cutting machines have revolutionized the way materials are processed in various industries. These machines utilize a thin wire with diamond segments to cut through hard materials, offering precision and efficiency that traditional cutting methods often lack. This article will explore the operation of wire saw cutting machines, their applications, advantages, and some considerations for potential users. By understanding how these machines work and where they can be applied, operators can enhance productivity and achieve better results in their projects.

Wire saw technology operates on the principle of using a continuous loop of wire that is tensioned and guided to create clean cuts. The wire is typically embedded with diamond particles, making it capable of cutting through extremely hard materials such as granite, marble, concrete, and silicon wafers. The process is not only efficient but also minimizes material waste compared to conventional saws. The precise nature of wire saw cutting means that intricate shapes and designs can be achieved with a high degree of accuracy.

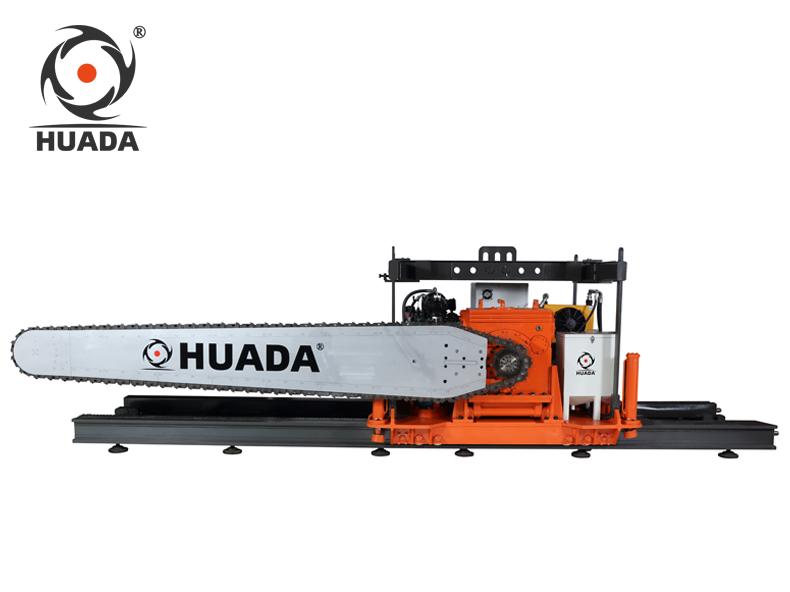

A typical wire saw cutting machine consists of several key components: the wire spool, drive system, tensioning mechanism, and guiding system. The wire spool holds the diamond wire, which is fed through the machine. The drive system powers the wire, enabling it to move at adjustable speeds, while the tensioning mechanism ensures that the wire remains taut during operation. The guiding system directs the wire along the intended cutting path, allowing for both straight cuts and more complex profiles.

Operating a wire saw cutting machine requires careful setup and calibration. Initially, the operator must select the appropriate diamond wire based on the material being cut. Once the machine is set up, the wire is threaded through the guides and tensioned properly. The machine's speed and feed rate are adjusted according to the specific material properties and desired cut size. As the wire moves, it creates a slurry of particles that helps cool the wire and flush out debris, further enhancing the cutting process.

Wire saw cutting machines have a wide range of applications across several industries. In the stone industry, they are commonly used for quarrying and processing natural stones like granite and marble. The precision of wire saws allows for the creation of slabs with uniform thickness, which is essential for many architectural applications. In the semiconductor industry, wire saws are utilized for slicing silicon wafers, where maintaining flatness and minimal kerf loss is critical. Furthermore, these machines are increasingly being adopted in the construction industry for cutting reinforced concrete and other dense materials.

The advantages of wire saw cutting machines are numerous. Firstly, they provide a cleaner cut with less chipping and cracking, especially in brittle materials. This leads to higher quality finishes and less material wastage. Secondly, the flexibility of wire saws allows for intricate cuts and shapes that would be challenging to achieve with traditional saws. Additionally, wire saws tend to operate at lower noise levels and produce less vibration, contributing to a safer working environment. Finally, their efficiency can lead to significant cost savings over time, as they reduce both labor and material costs.

When selecting a wire saw cutting machine, there are several factors to consider. The type of material to be cut is paramount, as different materials may require specific types of diamond wire and machine configurations. The size and capacity of the machine should also match the scale of operations, ensuring that it can handle the required workload. Additionally, operators should evaluate the machine's ease of use, maintenance requirements, and after-sales support from the manufacturer. Investing in training for operators can also enhance the efficiency and safety of machine operation.

As technology advances, the capabilities of wire saw cutting machines are expected to improve significantly. Innovations in diamond wire technology, including the development of new bonding materials and wire configurations, will increase cutting efficiency and longevity. Automation and integration with digital technologies will enhance precision and allow for real-time monitoring of the cutting process. These advancements will likely lead to even broader applications across various industries, making wire saws an indispensable tool in modern manufacturing.

Wire saw cutting machines represent a significant advancement in material processing technology. Their ability to deliver clean, precise cuts while minimizing waste has made them invaluable in industries ranging from stone processing to semiconductor manufacturing. By understanding the operation, applications, and advantages of wire saw cutting machines, businesses can make informed decisions that enhance productivity and quality. As technology continues to evolve, these machines will undoubtedly play a crucial role in shaping the future of cutting and manufacturing processes.