Author:Huada Quarrying Machine FROM:Stone quarry machine manufacturer TIME:2024-12-18

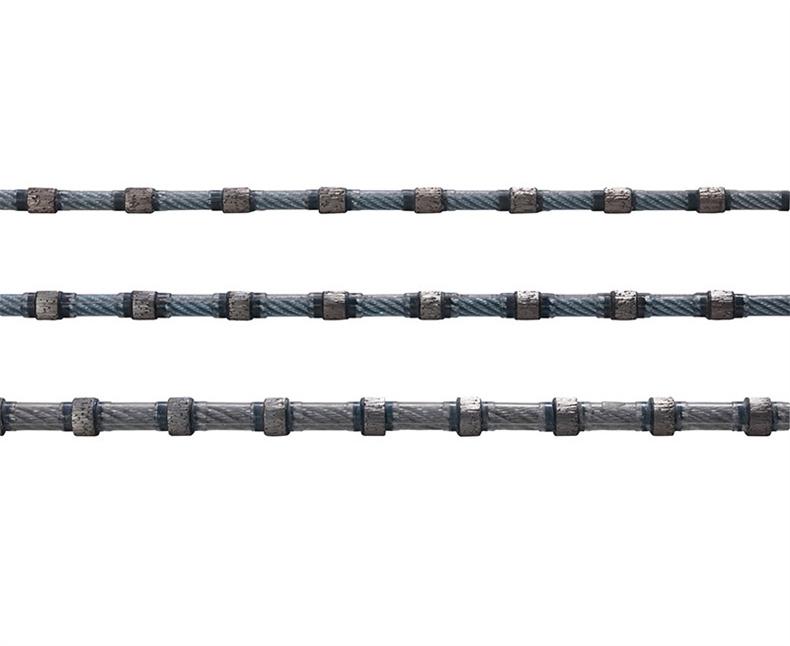

Diamond wire cutting is a revolutionary technique widely used in various industries for precise and efficient stone processing. The method involves using a wire embedded with diamond segments, allowing for clean cuts through various types of stones with minimal waste. This article explores the different types of stone that can be effectively cut using diamond wire technology, highlighting their unique properties and advantages in construction, sculpture, and other applications.

Granite is one of the most popular stones cut with diamond wire. Known for its durability and aesthetic appeal, granite is commonly used in countertops, flooring, and monuments. The hardness of granite makes it challenging to cut with traditional tools, but diamond wire provides a solution. The flexibility and precision of diamond wire allow for intricate designs and smooth finishes, making it a preferred choice for both residential and commercial projects.

Marble is another stone that benefits significantly from diamond wire cutting. Valued for its beauty and variety of colors, marble is often used in high-end architecture and art. The diamond wire technique allows for cleaner cuts compared to conventional saws, reducing the risk of chipping and cracking. This is particularly important when working with softer stones like marble, as even minor damage can affect the overall appearance. Furthermore, diamond wire cutting can achieve complex shapes and detailed carvings, enhancing the artistic potential of marble.

Limestone, with its sedimentary composition, is also well-suited for diamond wire cutting. This stone is widely used in building materials and landscaping due to its versatility and ease of manipulation. The diamond wire method allows for efficient cutting of limestone slabs, ensuring uniform thickness and smooth edges. Additionally, the reduced dust and debris produced during the cutting process make it an environmentally friendly option, appealing to contractors and builders focused on sustainability.

Quartzite, known for its strength and resistance to weathering, is increasingly being cut with diamond wire technology. This metamorphic rock is often used in exterior applications and high-traffic areas due to its durability. Diamond wire cutting is advantageous for quartzite because it allows for precise cuts without causing fractures, which is essential for maintaining the integrity of the stone. The ability to create large format tiles and slabs makes diamond wire cutting a preferred method for manufacturers and fabricators.

Sandstone, a softer stone compared to granite and quartzite, is also effectively processed using diamond wire. This type of stone is popular in landscaping and outdoor structures due to its natural look and ease of installation. The flexibility of diamond wire cutting enables the creation of various shapes and sizes, catering to specific design requirements. Additionally, the technique minimizes the risk of dust and damage, making it ideal for both rough and polished finishes.

Basalt, a volcanic rock known for its toughness, is increasingly cut using diamond wire methods. With its unique texture and color, basalt is often used in architectural features and landscaping. The use of diamond wire allows for precise cuts while preserving the stone's natural qualities. This method is particularly beneficial for larger projects where consistency and quality are critical, enabling architects and designers to realize their visions without compromise.

Soapstone, characterized by its softness and ability to be easily carved, is another stone that can be effectively cut using diamond wire. This stone is frequently used in countertops, sinks, and sculptures. While soapstone is easier to cut than harder stones, the diamond wire technique ensures smooth edges and intricate designs. Moreover, the reduced risk of breaking or chipping enhances the overall quality of the finished product.

While not a natural stone, concrete is often integrated with stone elements and can also be cut using diamond wire technology. The versatility of diamond wire makes it suitable for cutting reinforced concrete, allowing for precise dimensions and shapes. This application is particularly important in construction projects where accuracy is essential. The reduced noise and dust during cutting further improve the working conditions for construction teams.

In summary, diamond wire cutting technology has transformed the way various types of stones are processed. From granite and marble to limestone and basalt, the advantages of this method include precision, efficiency, and reduced material waste. As industries continue to seek innovative solutions for stone cutting, the versatility of diamond wire will remain at the forefront, accommodating a wide range of applications and enhancing the beauty and functionality of stone products. The ongoing development of diamond wire technology promises to further expand its capabilities, ensuring that it remains an indispensable tool in the stone processing industry.