Author:Huada Quarrying Machine FROM:Stone quarry machine manufacturer TIME:2024-12-16

Diamond wire saws are powerful tools used in various industries, including construction, mining, and manufacturing. For new users, understanding how to properly operate and maintain this equipment is crucial for both safety and efficiency. This article provides an overview of recommended training for new users of diamond wire saws, ensuring they can maximize the benefits of this technology while minimizing risks.

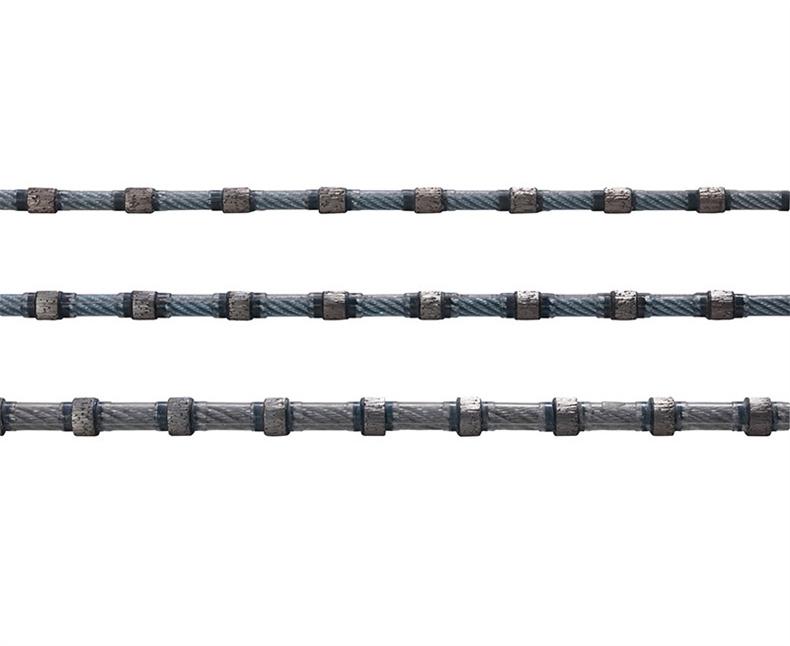

Before diving into operational training, it’s essential for new users to grasp the fundamentals of diamond wire technology. Diamond wire saws utilize a wire embedded with diamond segments to cut through hard materials like concrete, stone, and metal. The unique design allows for precise cuts with minimal waste and reduced dust compared to traditional sawing methods. New users should familiarize themselves with the different types of diamond wires available, their specific applications, and how they differ from conventional cutting tools.

Safety should always be the top priority when operating heavy machinery. New users must complete thorough safety training that covers the following key areas: proper personal protective equipment (PPE), safe handling practices, and emergency procedures. Users should learn about the importance of wearing safety goggles, gloves, and hearing protection to prevent injuries. Additionally, they should be trained on how to respond to potential hazards, such as wire breakage or equipment malfunction.

After completing safety training, users should engage in hands-on operational training. This training should include guidance on setting up the diamond wire saw, including aligning the wire, adjusting tension, and selecting the appropriate cutting speed. Trainees should practice operating the saw under supervision, gradually increasing their autonomy as they gain confidence and skill. Understanding how to make adjustments based on material type and thickness is also crucial for effective operation.

Proper maintenance is vital for maximizing the lifespan and performance of diamond wire saws. New users should receive training on routine maintenance tasks, such as cleaning the equipment, checking for wear and tear on the wire, and lubricating moving parts. They should learn how to identify signs of damage or wear, which could indicate a need for repair or replacement. Regular maintenance not only ensures safety but also enhances the efficiency of cutting operations.

Understanding common issues that may arise during operation is another critical aspect of training. New users should be taught how to troubleshoot problems such as wire breakage, misalignment, or inadequate cutting speed. Training should include practical scenarios where users can practice diagnosing issues and implementing solutions. This hands-on experience will prepare them for real-world challenges they may face while using the equipment.

Efficiency is key to productivity when using diamond wire saws. New users should be educated on best practices that can enhance cutting performance. This includes selecting the right type of diamond wire for specific materials, maintaining consistent cutting speeds, and understanding the importance of cooling fluids to reduce heat buildup. Training should also cover the benefits of planning cuts in advance to minimize waste and optimize workflow.

As industries become more environmentally conscious, new users of diamond wire saws should receive training on how to operate these tools with minimal environmental impact. This includes understanding dust control measures, managing water use during cutting, and disposing of waste materials responsibly. Training should emphasize the importance of adhering to local regulations regarding environmental protection and how sustainable practices can benefit both the industry and the community.

The field of diamond wire technology is constantly evolving, so ongoing training is essential for users to stay updated on the latest advancements. New users should be encouraged to participate in workshops, seminars, and online courses that focus on emerging techniques, new technologies, and improvements in safety practices. Continuous learning ensures that users remain competent and confident in their skills throughout their careers.

In conclusion, comprehensive training is essential for new users of diamond wire saws to ensure safe, efficient, and effective operation. From understanding the technology and safety protocols to mastering operational techniques and maintenance, each component of training plays a vital role in user success. By investing in thorough training and fostering a culture of continuous learning, organizations can empower their employees to harness the full potential of diamond wire technology while promoting a safe working environment.