Author:Huada Quarrying Machine FROM:Stone quarry machine manufacturer TIME:2024-12-03

In recent years, the construction and manufacturing industries have been increasingly focused on sustainability and reducing their environmental impact. One innovative solution that has gained traction is the use of diamond wire saws. These advanced cutting tools offer numerous environmental benefits compared to traditional cutting methods. This article will explore the various ways in which diamond wire technology contributes to a more sustainable future by minimizing waste, enhancing energy efficiency, and reducing emissions.

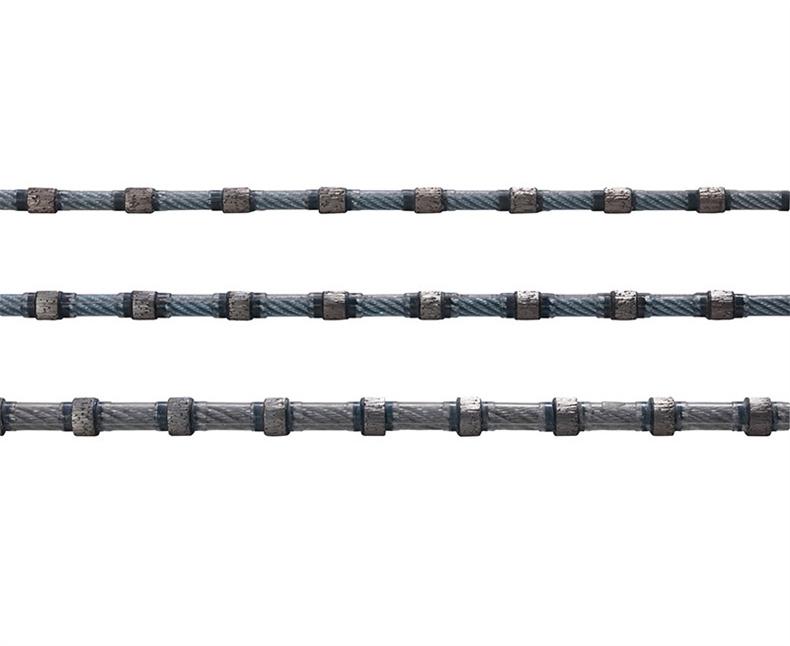

One of the most significant environmental benefits of using diamond wire saws is their ability to minimize material waste. Traditional cutting methods often result in substantial excess material being produced, particularly when working with hard materials like concrete and stone. Diamond wire saws, however, utilize a thin, flexible wire embedded with diamond particles, allowing for more precise cuts. This precision means less material is wasted during the cutting process, contributing to more efficient resource utilization.

For example, when cutting large blocks of stone, conventional methods may leave behind large chunks that are unusable. In contrast, diamond wire saws can be adjusted to create smaller, more accurate cuts, ensuring that nearly all the material can be utilized effectively. This reduction in waste not only conserves natural resources but also decreases the need for additional raw material extraction, further benefiting the environment.

Energy consumption is another critical factor in assessing the environmental impact of cutting technologies. Diamond wire saws are designed to be more energy-efficient than traditional cutting methods. The cutting action of diamond wire requires less power, as it generates less friction and heat during operation. This reduced energy requirement translates to lower electricity consumption, which is particularly important in industries that operate large machinery and equipment.

By utilizing diamond wire saws, companies can significantly decrease their overall energy usage, leading to a smaller carbon footprint. This is especially pertinent in regions where energy production relies heavily on fossil fuels. Transitioning to more energy-efficient cutting techniques can therefore contribute to climate change mitigation efforts by reducing greenhouse gas emissions associated with energy production.

The cutting process itself can generate considerable pollution, primarily through dust and particulate matter. Diamond wire saws produce significantly less dust compared to traditional sawing methods. The enclosed cutting technique used in diamond wire applications helps contain dust, making it easier to manage and reduce environmental contamination.

Moreover, the reduced energy requirements of diamond wire saws lead to fewer emissions from machinery. As industries adopt cleaner technologies, the overall air quality improves, benefiting both workers and nearby communities. This reduction in pollutants is crucial for promoting a healthier environment and aligns with global efforts to improve air quality standards.

Another noteworthy aspect of diamond wire technology is the sustainability of the materials used in its production. Diamonds, while traditionally associated with luxury, are now being synthesized and repurposed for industrial applications. Synthetic diamonds used in wire saws can be produced with minimal environmental impact compared to mined diamonds. Additionally, the longevity and durability of diamond wire saws mean that they require less frequent replacement, reducing the overall demand for new materials.

This shift towards using synthetic diamonds not only lessens the environmental toll of mining operations but also helps to promote a circular economy. By focusing on sustainable materials and practices, industries can contribute positively to the environment while still meeting their operational needs.

The economic advantages of using diamond wire saws also play a role in fostering environmental stewardship within industries. While the initial investment in diamond wire technology may be higher than traditional cutting methods, the long-term savings in material costs, energy consumption, and waste management make it a financially sound choice. As businesses recognize these benefits, they are more likely to invest in environmentally friendly technologies.

This shift not only promotes sustainable practices but also encourages innovation within the industry. Companies that prioritize eco-friendly solutions often attract environmentally conscious consumers, enhancing their brand reputation and market position. Thus, the economic incentives align with environmental goals, creating a win-win scenario.

In conclusion, the adoption of diamond wire technology presents a multitude of environmental benefits that cannot be overlooked. From minimizing material waste and enhancing energy efficiency to reducing emissions and promoting sustainable materials, diamond wire saws represent a significant advancement in cutting technology. As industries continue to seek ways to reduce their environmental impact, the transition to diamond wire saws offers a viable path forward.

By embracing innovative solutions like diamond wire technology, we can work towards a more sustainable future while still meeting the demands of modern construction and manufacturing. It is imperative that we continue to explore and implement such technologies to ensure that our practices align with the principles of environmental stewardship and responsibility.