Author:Huada Quarrying Machine FROM:Stone quarry machine manufacturer TIME:2024-11-30

Cutting curves and intricate designs using diamond wire is an advanced technique widely employed in various industries, including stone processing, construction, and manufacturing. This method allows for precise cuts with minimal waste, making it ideal for delicate and complex shapes. In this article, we will explore the best practices for effectively utilizing diamond wire to achieve superior results in your cutting projects.

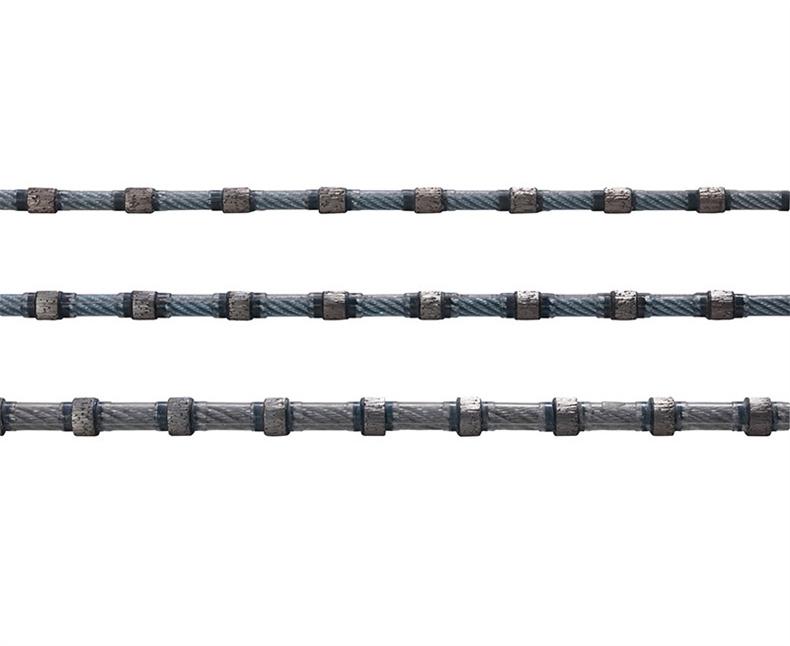

Diamond wire cutting technology utilizes a steel wire embedded with diamond segments. The diamonds provide the cutting capability, while the wire's flexibility allows for intricate movements around curves and shapes. This combination makes diamond wire cutting superior to traditional methods, especially for hard materials like granite, concrete, and ceramics. Understanding how this technology works is essential for maximizing its potential in your cutting tasks.

Selecting the appropriate equipment is crucial for successful diamond wire cutting. This includes the diamond wire saw, which should be suited to the specific material you are cutting. Various types of diamond wire are available, with differences in diameter, bond type, and diamond concentration. For intricate designs, a thinner wire may offer better precision, while a thicker wire can enhance durability for larger cuts. Additionally, ensure that your machine has adjustable speed settings to accommodate different cutting requirements.

Before beginning any cutting process, proper preparation of the material is vital. Ensure that the material is clean and free from debris, as contaminants can interfere with the cutting process and lead to poor results. Marking your design on the surface can also help guide the cutting process. Utilize templates or guides if necessary, especially for highly detailed or curved designs. Properly securing the material is equally important; use clamps or fixtures to stabilize it and prevent movement during cutting.

Calibrating your diamond wire saw before cutting is essential for achieving accurate results. Check the alignment of the wire and ensure it is tensioned correctly. An improperly tensioned wire can lead to inaccurate cuts and increased wear on the wire itself. Additionally, setting the correct cutting speed is critical; too fast may cause excessive wear and tear, while too slow can lead to inefficient cutting. Take the time to adjust these settings according to the material type and desired outcome.

When cutting curves and intricate designs, employing the right techniques is key. Start with shallow cuts to establish your pattern before progressing to deeper cuts. This approach allows for better accuracy and reduces the risk of wire breakage. Use a steady hand and maintain a consistent feed rate to ensure smooth cutting. For complex curves, consider using a programmed CNC machine that can automate the cutting process, providing a higher level of precision and reducing manual errors.

Continuous monitoring during the cutting process is essential. Pay attention to the speed and movement of the wire, ensuring it does not bow or deviate from the intended path. Regularly check for signs of wire wear or overheating, as these can indicate the need for adjustments. Keeping a close eye on these factors will help maintain the integrity of both the material and the diamond wire, ultimately leading to cleaner cuts and longer tool life.

After completing the cuts, proper finishing techniques are necessary to enhance the overall appearance of the workpiece. This may include sanding or polishing the edges to remove any rough spots left by the cutting process. Inspect the finished product for any imperfections, and make necessary adjustments to ensure that the design meets your standards. Cleaning the work area and tools after cutting is also important for maintaining the equipment and prolonging its lifespan.

Safety should always be a priority when working with diamond wire cutting systems. Wear appropriate personal protective equipment, including gloves, goggles, and hearing protection. Ensure that your workspace is well-ventilated to prevent dust accumulation and respiratory hazards. Familiarize yourself with the equipment’s safety features and operational guidelines to mitigate risks associated with machinery and cutting processes.

In conclusion, cutting curves and intricate designs with diamond wire requires a thoughtful approach that encompasses understanding the technology, selecting the right equipment, and employing effective cutting techniques. By following these best practices, you can achieve precision cuts while minimizing waste and maximizing efficiency. Whether you are a seasoned professional or a newcomer to diamond wire cutting, implementing these strategies will help enhance your skills and elevate the quality of your work.