Author:Huada Quarrying Machine FROM:Stone quarry machine manufacturer TIME:2024-11-29

Diamond wire cutting technology has revolutionized various industries, from construction to mining and even solar panel manufacturing. The machines designed for using diamond wire offer precision, efficiency, and versatility, making them essential tools in modern operations. This article will explore the best machines for utilizing diamond wire, highlighting their features, benefits, and applications.

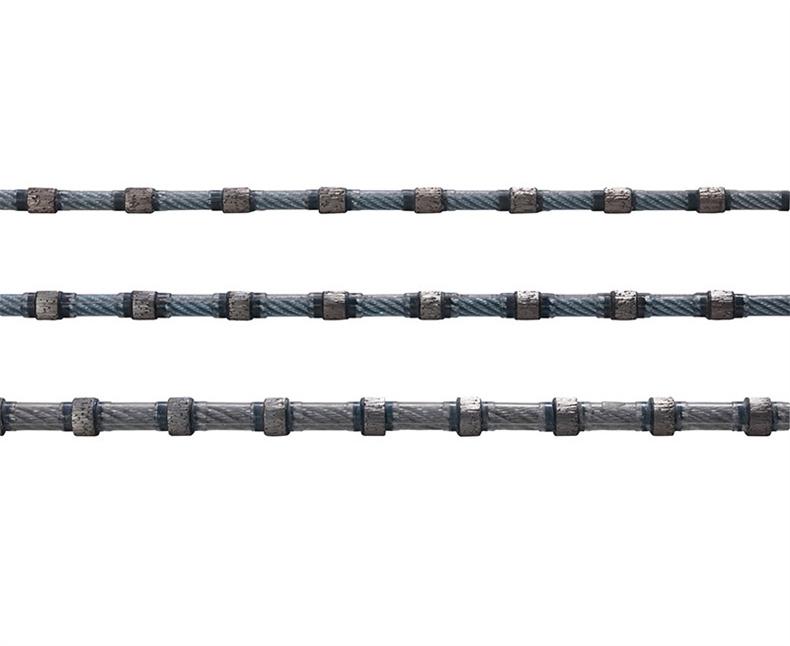

Before diving into the machines themselves, it’s important to understand what diamond wire cutting entails. This technique uses a wire embedded with diamond segments to cut through hard materials like concrete, granite, and various metals. The process is known for its ability to create clean cuts with minimal waste, making it an environmentally friendly option. Machines that facilitate diamond wire cutting are designed to maximize these advantages, ensuring optimal performance in diverse applications.

There are several types of machines that utilize diamond wire, each tailored for specific applications. The most common types include stationary saws, mobile saws, and wire saws used in specialized industries. Each type offers unique benefits that cater to different operational needs.

Stationary diamond wire saws are typically used in workshops and manufacturing facilities. These machines are anchored in place and provide robust cutting capabilities for large blocks of stone or concrete. They often feature sophisticated controls that allow for precise adjustments in speed and wire tension, which enhances cutting accuracy. Ideal for high-volume production, these saws can handle multiple cuts simultaneously, increasing operational efficiency.

Mobile diamond wire saws are designed for portability, making them perfect for on-site projects. These machines are equipped with wheels and can be easily transported to various locations, allowing for flexibility in operations. They are commonly used in demolition projects, where quick and efficient cutting is necessary to navigate complex structures. Despite their mobility, they maintain a high level of power and precision, providing a reliable solution for challenging cutting tasks.

Computer Numerical Control (CNC) diamond wire cutting machines represent the pinnacle of precision in the industry. These machines are controlled by computer programs that dictate the cutting path, speed, and depth, allowing for intricate designs and shapes. CNC machines are widely used in industries such as jewelry making and custom fabrication, where detail is paramount. The automation provided by CNC technology also reduces the risk of human error, leading to consistent and high-quality results.

Diamond wire cutting machines are utilized across various sectors, showcasing their versatility. In the construction industry, they are essential for cutting reinforced concrete and masonry, enabling safer and more efficient demolitions. In the stone industry, these machines facilitate the extraction and processing of natural stone, ensuring smooth finishes and minimal waste. Additionally, the solar panel industry relies on diamond wire cutting for slicing silicon wafers, demonstrating the technology's importance in renewable energy production.

When selecting a diamond wire cutting machine, several features should be taken into account. Power and motor capabilities are crucial; a powerful motor ensures that the machine can handle tough materials without overheating or slowing down. Additionally, the wire feed mechanism plays a significant role in maintaining the wire's tension and speed, which directly affects cutting efficiency. Other considerations include the machine's weight, portability, and ease of operation, particularly for mobile units.

The cost of diamond wire cutting machines can vary significantly based on their type, features, and brand. While stationary saws may offer higher initial investments due to their advanced technology and capabilities, they often lead to long-term savings through increased efficiency and reduced material waste. Conversely, mobile machines may be less expensive but could incur additional costs related to transport and operational logistics. It’s essential to evaluate the total cost of ownership, including maintenance and operational expenses, when making a purchasing decision.

As technology advances, the future of diamond wire cutting appears promising. Innovations such as improved diamond segment formulations and enhanced machine automation are expected to increase cutting speeds and efficiencies further. Additionally, the integration of artificial intelligence in machine operations may allow for real-time monitoring and adjustments, optimizing performance and reducing downtime. Sustainability will also drive innovation, with manufacturers focusing on creating machines that minimize waste and energy consumption.

In summary, the best machines for using diamond wire vary based on application, mobility, and technological advancements. Stationary and mobile saws cater to different operational requirements, while CNC machines offer unparalleled precision. When selecting a machine, consider its features, cost, and the specific demands of your projects. With the right equipment, businesses can leverage diamond wire cutting technology to achieve superior results in efficiency, accuracy, and sustainability.