Author:Huada Quarrying Machine FROM:Stone quarry machine manufacturer TIME:2024-11-28

In the realm of cutting technologies, diamond wire saws have emerged as a revolutionary alternative to traditional saws. This advancement offers numerous advantages in various industries, particularly in construction, stone processing, and even in the manufacturing of solar panels. Understanding the benefits of diamond wire over traditional saws is crucial for businesses looking to optimize their cutting methods, increase efficiency, and reduce costs. This article explores the key advantages of diamond wire saws, including precision, efficiency, versatility, and safety.

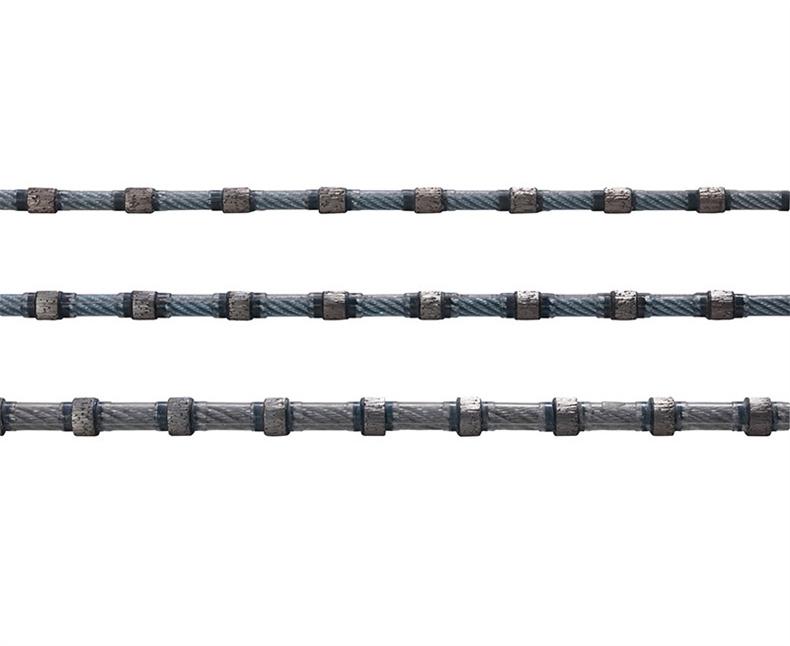

One of the most significant advantages of using diamond wire saws is the precision they offer. Traditional saws often struggle to achieve the level of accuracy required for intricate cuts, especially in hard materials like granite or reinforced concrete. Diamond wire saws utilize a thin wire embedded with diamond segments, allowing for extremely fine cuts with minimal kerf loss. This precision minimizes material wastage and ensures that the final product meets the exact specifications required by clients.

Efficiency is another area where diamond wire saws excel. They operate at higher speeds than traditional saws, significantly reducing cutting time. The continuous loop of the diamond wire allows for uninterrupted cutting, leading to faster project completion times. Additionally, the reduced friction generated during the cutting process means less energy consumption, which translates into lower operational costs. This efficiency not only benefits the bottom line but also enhances overall productivity on job sites.

Diamond wire saws are incredibly versatile and can cut through a wide range of materials, from soft stones to the hardest metals. Unlike traditional saws, which may require different blades for different materials, a diamond wire saw can adapt to various cutting tasks with ease. This versatility makes them an ideal choice for industries such as construction, mining, and manufacturing, where diverse materials are encountered regularly. Companies can streamline their operations by investing in a single tool capable of handling multiple cutting jobs.

The environmental benefits of diamond wire saws cannot be overlooked. Traditional saws often produce a considerable amount of waste due to their thicker blades and less efficient cutting methods. In contrast, the slim nature of diamond wire results in a smaller kerf, which leads to less material loss. Furthermore, the reduced energy consumption associated with diamond wire cutting contributes to a lower carbon footprint. For companies looking to enhance their sustainability practices, switching to diamond wire saws is a step in the right direction.

Safety is a paramount concern in any cutting operation. Diamond wire saws are designed with safety in mind. Their design minimizes kickback and vibration, which can be common hazards with traditional saws. Additionally, the enclosed cutting mechanism reduces the risk of debris and dust exposure to operators. This enhanced safety profile not only protects workers but also lowers the likelihood of costly accidents and the associated downtime.

While the initial investment in diamond wire saw technology may be higher than that of traditional saws, the long-term cost-effectiveness is undeniable. The durability of diamond wire leads to longer lifespans compared to conventional blades, resulting in fewer replacements and maintenance costs. Moreover, the efficiency gains translate into lower labor costs, as projects can be completed more quickly. Over time, businesses will find that the return on investment far outweighs the initial expenditure.

Maintenance is a critical aspect of any cutting tool's longevity and performance. Diamond wire saws require considerably less maintenance compared to traditional saws. The wear and tear on diamond wire is minimal, and regular checks are often sufficient to ensure optimal performance. This low maintenance requirement not only saves time but also reduces the operational disruptions that can occur when tools need extensive repairs or replacements.

In conclusion, the advantages of using diamond wire saws over traditional saws are clear. From precision cutting and improved efficiency to versatility and enhanced safety, diamond wire technology demonstrates its superiority across multiple facets of cutting operations. As industries continue to evolve and demand higher standards, embracing modern cutting technologies like diamond wire saws will be essential for staying competitive. By investing in these advanced tools, businesses can enhance their productivity, reduce costs, and contribute to a more sustainable future.