Author:Huada Quarrying Machine FROM:Stone quarry machine manufacturer TIME:2024-11-27

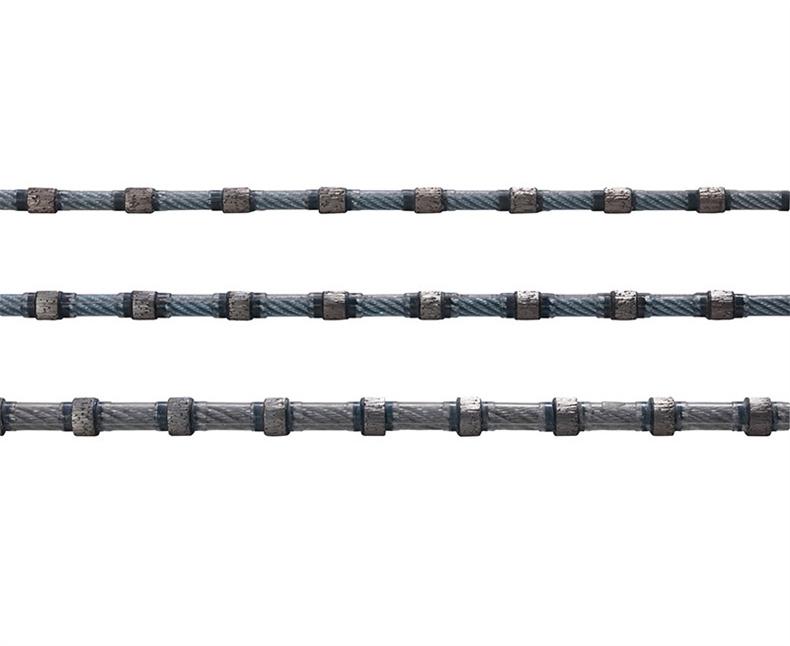

Diamond wire saws have revolutionized the stone industry, offering unparalleled efficiency and precision in cutting various types of stone. Unlike traditional cutting methods, diamond wire technology employs a series of diamond-coated wires that can slice through hard materials with minimal waste and superior speed. This article explores the common applications of diamond wire in the stone industry, highlighting its benefits and versatility.

One of the most significant applications of diamond wire in the stone industry is quarrying. Diamond wire saws are used extensively to extract large blocks of stone from quarries. The ability of these saws to cut through rock with exceptional accuracy reduces the risk of damaging the stone, thus preserving its quality. Furthermore, the lightweight nature of the wire allows for easier maneuverability in challenging quarry environments, making it a preferred choice among stone producers.

After stones are quarried, they often require block dressing to achieve the desired dimensions and surface finish. Diamond wire saws excel in this process due to their ability to make precise cuts without excessive chipping or cracking. This ensures that the blocks are uniform in size, making them easier to work with in subsequent processing stages. Additionally, the smooth edges produced by diamond wire contribute to a better aesthetic appearance, which is crucial for high-end applications.

Slab cutting is another vital application for diamond wire in the stone industry. Once blocks have been dressed, they need to be transformed into slabs for further use in construction and decoration. Diamond wire saws can efficiently cut thick blocks into thinner slabs while maintaining a high level of precision. This capability not only maximizes yield but also minimizes material waste, making diamond wire saws a cost-effective solution for slab production.

In addition to cutting, diamond wire saws are also employed for shaping and profiling stone. This application is particularly important in the creation of intricate designs and custom shapes required in architectural and artistic projects. The flexibility of the wire allows it to navigate complex curves and angles, enabling artisans and manufacturers to achieve detailed finishes that would be difficult with traditional cutting tools.

Surface finishing is crucial in enhancing the aesthetic appeal of stone products. Diamond wire technology facilitates various finishing processes, including honing and polishing. By using finer diamond wires, manufacturers can achieve smooth surfaces that are not only visually appealing but also resistant to wear and damage. This application is especially beneficial for stone products used in high-traffic areas, where durability is essential.

Diamond wire saws play a pivotal role in restoration projects, particularly in historical buildings and monuments. When restoring aged stone structures, maintaining the integrity of the original material is paramount. Diamond wire saws allow restorers to carefully cut and remove damaged sections without causing further harm to adjacent areas. This precision is crucial in preserving the historical value and structural stability of the building.

Beyond their practical applications, diamond wire saws also offer environmental benefits. Traditional cutting methods often generate significant amounts of waste and dust, which can be harmful to both workers and the environment. In contrast, diamond wire technology produces less waste and minimizes dust generation, contributing to a cleaner and safer working environment. This eco-friendly aspect is increasingly important as the industry moves towards more sustainable practices.

Cost efficiency is a major consideration for any business in the stone industry. Diamond wire saws, while initially more expensive than traditional tools, offer long-term savings through increased productivity and reduced material waste. The longevity of diamond wires, combined with their ability to cut faster and more accurately, results in lower operational costs over time. As such, many companies are investing in diamond wire technology to improve their bottom line.

Another advantage of diamond wire saws is their versatility across various types of stone. Whether working with granite, marble, limestone, or even concrete, diamond wire technology can adapt to different materials. This versatility makes it an invaluable tool for stone fabricators who handle multiple stone types and need consistent results across their product range. With diamond wire saws, operators can switch between materials without the need for significant adjustments to their equipment.

In summary, diamond wire saws have become integral to the stone industry due to their numerous applications and benefits. From quarrying and block dressing to shaping and restoration, their precision, efficiency, and environmental advantages set them apart from traditional cutting methods. As the industry continues to evolve, the adoption of diamond wire technology will likely expand, further enhancing the capabilities of stone producers and fabricators alike. Embracing this advanced technology not only improves operational outcomes but also contributes to a more sustainable and economically viable future for the stone industry.