Author:Huada Quarrying Machine FROM:Stone quarry machine manufacturer TIME:2024-11-15

Determining the right tension for diamond wire is crucial for optimizing cutting performance and ensuring the longevity of the wire itself. As diamond wire saws become increasingly popular in various industries, understanding how to achieve the appropriate tension can significantly impact efficiency and quality. This article explores the factors that influence diamond wire tension and provides guidelines for achieving the ideal setup.

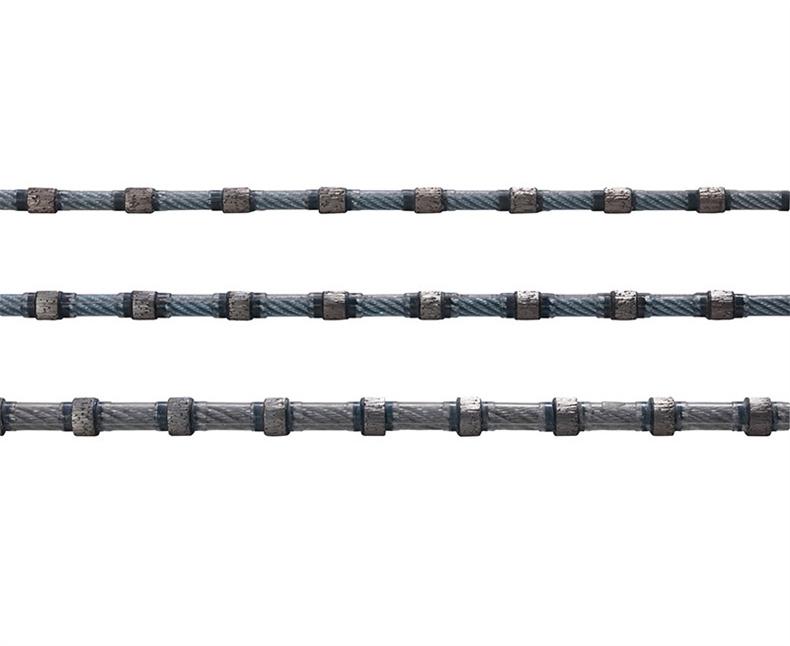

Diamond wire sawing utilizes a thin wire with diamond segments attached to cut through materials like concrete, stone, and metal. The wire’s tension plays a pivotal role in its cutting effectiveness. If the tension is too low, the wire may snap or fail to cut efficiently; if it’s too high, it could lead to excessive wear and tear or equipment damage. Thus, finding the right balance is essential.

Several factors come into play when determining the appropriate tension for diamond wire. These include the type of material being cut, the diameter of the wire, the machine’s specifications, and environmental conditions. Understanding these factors helps operators make informed decisions regarding wire tension.

The properties of the material being cut greatly influence the necessary tension. Harder materials, such as granite or reinforced concrete, require higher tension to ensure efficient cutting. In contrast, softer materials may need less tension to avoid damaging the wire. Operators should assess the material’s density, hardness, and brittleness to determine the optimal tension settings.

The diameter of the diamond wire also impacts tension requirements. Thicker wires generally require higher tension due to their increased mass. Conversely, thinner wires can operate effectively at lower tensions. Additionally, different types of diamond wires, such as those designed for specific applications (e.g., wet vs. dry cutting), may have unique tension requirements based on their construction and intended use.

The capabilities of the sawing machine are another critical factor. Machines are designed with specific tension ranges that should not be exceeded. Operators must consult the manufacturer's guidelines to understand the recommended tension settings for their equipment. Adjusting the tension outside these parameters can lead to performance issues and potential damage to both the machine and the wire.

Environmental factors such as temperature and humidity can also affect wire tension. High temperatures may cause the wire to expand, altering its tension. On the other hand, colder environments might contract the wire, requiring adjustments. Humidity levels can also influence the cutting process, particularly in wet cutting scenarios. Operators should monitor these conditions and adjust tension accordingly to optimize performance.

Adjusting diamond wire tension involves a few straightforward techniques. Most modern machines come equipped with tensioning systems that allow operators to easily modify settings. It is advisable to start with the manufacturer’s recommended tension and make small adjustments based on observed performance. Regular monitoring during operation can help identify the need for further adjustments.

Continuous monitoring is essential to ensure that the diamond wire operates within the desired tension range. Operators should look for signs of wear, such as increased vibration, unusual noise, or decreased cutting efficiency. Implementing a regular maintenance schedule can help identify issues early on and prevent more significant problems down the line.

Testing different tension settings can provide valuable insights into what works best for specific applications. Operators can conduct trials by adjusting the tension and observing the results. Keeping detailed records of performance metrics, such as cutting speed and wire lifespan, can help refine future tension settings and improve overall efficiency.

Safety is paramount when working with diamond wire saws. Improper tension can lead to wire breakage, posing a risk to operators and bystanders. Ensuring that all personnel are trained in proper handling procedures and aware of tension settings is crucial. Regular safety checks should be integrated into operational protocols to mitigate risks associated with equipment failure.

Determining the right tension for diamond wire is a multifaceted process that requires careful consideration of various factors, including material characteristics, wire diameter, machine specifications, and environmental conditions. By understanding these influences and implementing effective tension adjustment techniques, operators can enhance cutting performance and prolong the life of their diamond wire. Regular monitoring and testing are essential to maintain optimal tension settings, ensuring safety and efficiency in all cutting operations.