Author:Huada Quarrying Machine FROM:Stone quarry machine manufacturer TIME:2024-11-13

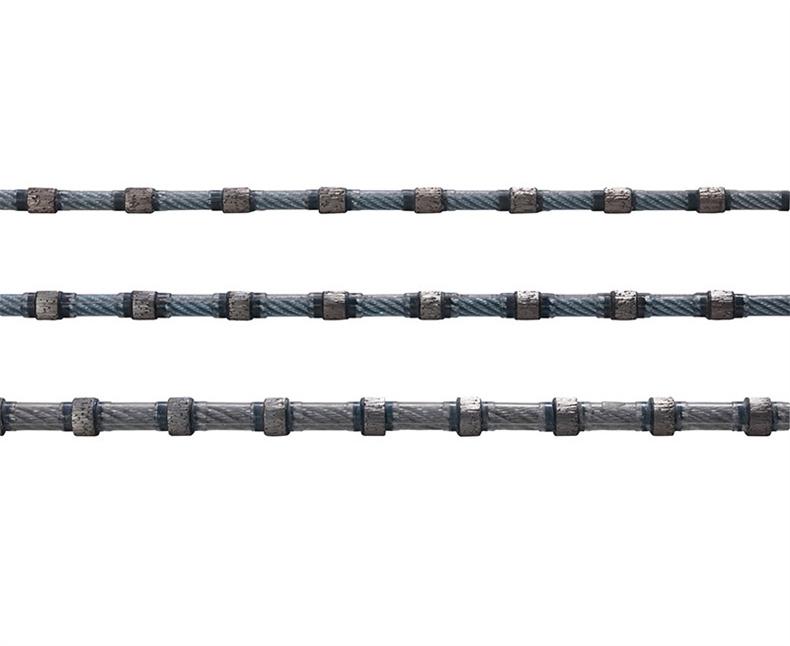

Diamond wire cutting is an advanced technology widely used in various industries, particularly in construction and manufacturing. It employs a wire embedded with diamond segments to cut through hard materials, offering precision and efficiency. As businesses seek to optimize operations, understanding the cost-effectiveness of diamond wire cutting becomes crucial. This article outlines the methods for calculating cost-effectiveness, including factors that need consideration, advantages of the technique, and how to compare it with traditional cutting methods.

Cost-effectiveness is a measure of the relative costs and outcomes associated with a particular process or technology. In the context of diamond wire cutting, it involves analyzing the costs incurred during the operation against the benefits gained, such as time savings, improved quality, and reduced waste. To accurately calculate cost-effectiveness, businesses must consider both direct and indirect costs involved in the cutting process.

The direct costs associated with diamond wire cutting primarily include materials, labor, and equipment maintenance. The cost of diamond wire itself can be significant, depending on the quality and type needed for specific applications. Additionally, skilled labor is required to operate and maintain the machinery effectively, which can add to overall expenses. Regular maintenance of cutting equipment also contributes to direct costs, as it ensures machinery remains efficient and safe for use.

In addition to direct costs, indirect costs play a vital role in determining the overall cost-effectiveness of diamond wire cutting. These may include overhead costs like utilities, facility maintenance, and insurance. Moreover, downtime due to machinery failure or maintenance schedules can lead to lost productivity, further impacting profitability. Calculating these indirect costs accurately is essential to obtain a comprehensive view of the financial implications of using diamond wire cutting technology.

One of the primary advantages of diamond wire cutting is its remarkable speed and efficiency compared to traditional cutting methods. The cutting process is generally quicker, leading to shorter project timelines and increased productivity. To calculate the cost-effectiveness, businesses should assess the amount of time saved on each project and translate that into monetary terms. By comparing the time taken for diamond wire cutting versus other methods, companies can better understand the potential for profit maximization.

The quality of the cut produced by diamond wire cutting is often superior to that achieved with conventional methods. A cleaner and more precise cut not only enhances the final product's appearance but also reduces material waste. Minimizing waste translates directly into cost savings. Therefore, when evaluating cost-effectiveness, it is essential to quantify the amount of material saved and the potential revenue generated from higher-quality outputs.

To fully understand the cost-effectiveness of diamond wire cutting, businesses should conduct a comparative analysis with traditional cutting methods such as saws or abrasive cutting techniques. This comparison should include direct costs, productivity rates, quality of cuts, and any additional benefits unique to diamond wire cutting. By performing this side-by-side analysis, companies can make informed decisions about which cutting method aligns best with their operational goals and budget constraints.

While initial costs for implementing diamond wire cutting technology may seem high, it is important to consider the long-term investment benefits. Over time, the efficiencies gained can result in significant cost savings. Businesses should analyze the total cost of ownership, factoring in equipment lifespan, maintenance costs, and the overall return on investment (ROI). This long-term perspective helps in making strategic decisions about adopting new technologies.

Examining real-world case studies where diamond wire cutting has been implemented can provide valuable insights into its cost-effectiveness. For instance, projects in the construction industry often cite reduced operational costs and enhanced safety due to the precise nature of the cuts. Analyzing specific examples allows businesses to see practical outcomes and gauge how similar implementations could benefit their operations.

Calculating the cost-effectiveness of diamond wire cutting involves a thorough analysis of both direct and indirect costs, along with an assessment of productivity gains and quality improvements. By understanding the various factors that contribute to cost-effectiveness, businesses can make informed decisions about adopting this cutting-edge technology. Ultimately, the right approach can lead to enhanced efficiency, reduced waste, and significant long-term savings, positioning companies favorably in competitive markets.