Author:Huada Quarrying Machine FROM:Stone quarry machine manufacturer TIME:2024-11-13

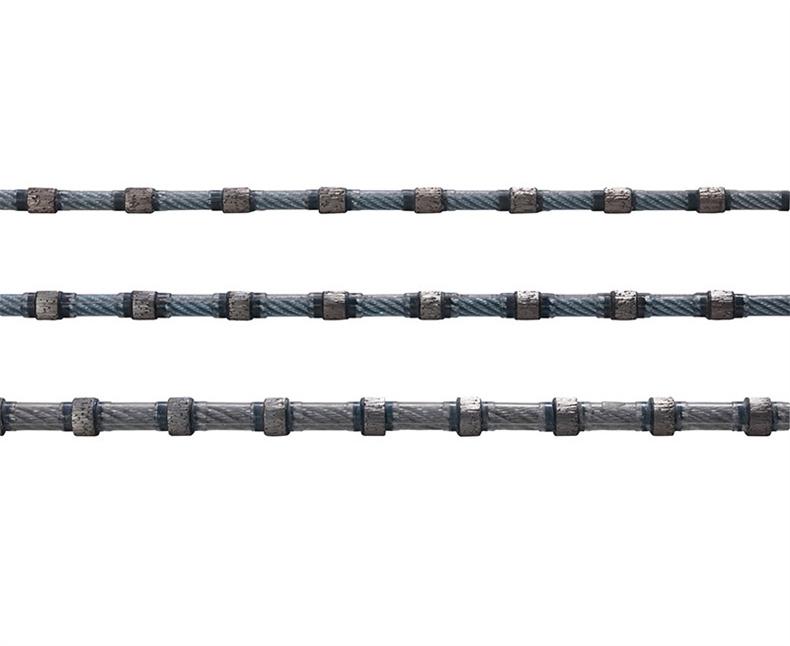

Diamond wire saws have become increasingly popular in various industries, particularly in the cutting of hard materials such as stone, concrete, and silicon. These tools rely on the unique properties of diamonds to provide precision cutting with minimal waste. However, the performance of diamond wire saws can be significantly influenced by environmental factors, particularly temperature and humidity. Understanding how these elements affect the operation and efficiency of diamond wire saws is crucial for optimizing their performance and extending their lifespan.

Temperature plays a significant role in the performance of diamond wire saws. As the operating temperature increases, several factors come into play that can enhance or hinder the cutting efficiency. High temperatures can lead to thermal expansion of the materials being cut, which may alter the characteristics of the cutting edge. Additionally, increased temperatures can affect the binding agents used in diamond wire production, potentially leading to reduced bond strength and premature wear of the wire.

When the temperature rises during cutting operations, the friction between the diamond particles and the material being cut also increases. This heightened friction can cause the diamonds to wear down more quickly than at lower temperatures, resulting in a shorter lifespan for the wire. Furthermore, excessive heat can lead to thermal degradation of the resin or metal matrix that holds the diamonds, further compromising the tool's effectiveness. Operators often need to adjust their cutting speeds and techniques to manage heat build-up effectively.

Conversely, low temperatures can also negatively impact diamond wire performance. At lower temperatures, materials can become more brittle, increasing the likelihood of chipping or cracking during the cutting process. This brittleness can lead to uneven cutting surfaces and reduced overall efficiency. Moreover, the lubricating properties of fluids used in conjunction with diamond wire saws may diminish in colder conditions, leading to increased friction and wear on the wire itself.

Humidity levels in the environment can also play a critical role in the performance of diamond wire saws. High humidity can affect the cutting process in several ways, primarily through its impact on the operational conditions and the materials used. Moisture in the air can interact with the cutting materials, potentially leading to rust or corrosion, especially in metal components of the wire saw. This deterioration can significantly impair the wire's performance and longevity.

In high humidity environments, the accumulation of moisture can create a slippery surface, which may affect the adhesion of the diamond particles to the matrix. This reduced adhesion can lead to premature diamond loss during cutting operations. Additionally, excessive moisture can create challenges in maintaining optimal cutting speeds, as operators may need to compensate for changes in friction and resistance caused by wet conditions.

On the other end of the spectrum, low humidity levels can lead to increased dust and debris generation during cutting processes. This dust can accumulate on the cutting surface, leading to clogging and overheating of the diamond wire. The lack of moisture can also affect the cooling properties of any lubricants used, further exacerbating wear and tear on the wire. Operators working in dry conditions may need to implement additional cooling measures to maintain optimal performance.

To ensure optimal performance of diamond wire saws amidst varying temperature and humidity conditions, several strategies can be employed. First, regular maintenance and inspection of the diamond wire are essential to identify any signs of wear or damage early. Additionally, operators should consider adjusting cutting speeds and techniques based on environmental conditions. Using appropriate lubricants that can withstand specific temperatures and humidity levels will also enhance the performance and lifespan of the diamond wire.

In conclusion, both temperature and humidity significantly influence the performance of diamond wire saws. Understanding these effects allows operators to make informed decisions that enhance cutting efficiency and prolong the life of their tools. By adopting best practices tailored to environmental conditions, users can optimize their diamond wire performance, ensuring successful outcomes in their cutting projects. Emphasizing proactive maintenance and environmental awareness will lead to improved productivity and reduced costs in the long run.