Author:Huada Quarrying Machine FROM:Stone quarry machine manufacturer TIME:2024-11-13

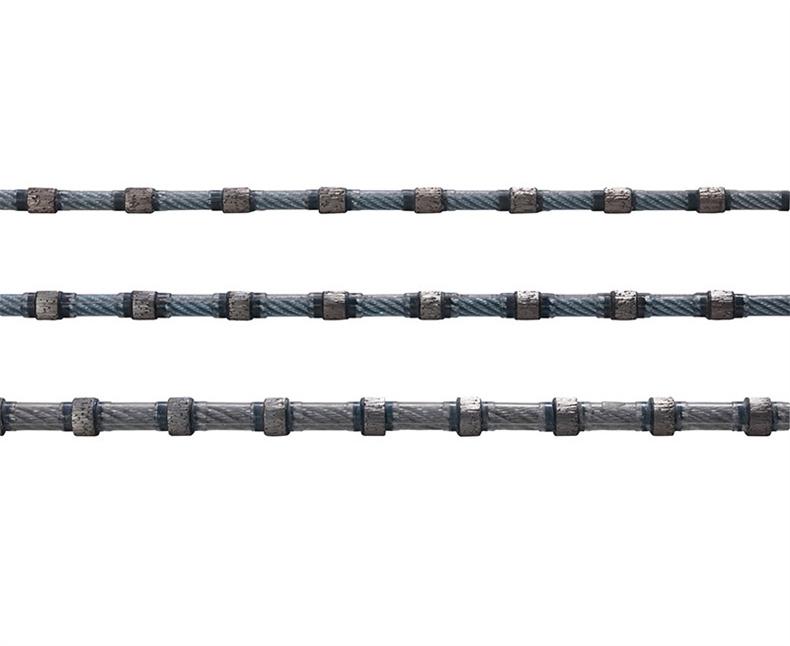

Diamond wire cutting is a widely used technique in various industries, particularly in stone and concrete cutting. This method utilizes a wire embedded with diamond particles to slice through materials with precision and efficiency. However, the effectiveness of diamond wire cutting can be significantly influenced by environmental conditions. Factors such as temperature, humidity, and the presence of contaminants can alter the performance of cutting tools, affect the wear rate of the diamond wire, and influence the overall quality of the cut. In this article, we will explore how these environmental conditions impact the diamond wire cutting process.

Temperature plays a crucial role in the performance of diamond wire cutting. High temperatures can lead to thermal expansion of both the wire and the material being cut, which may affect cutting accuracy. Additionally, elevated temperatures can accelerate the wear of the diamond particles, reducing the wire's lifespan. Conversely, extremely low temperatures can cause brittleness in the cutting wire, making it prone to breakage. Maintaining an optimal temperature range is essential to ensure effective cutting and prolong the life of diamond wires.

Humidity levels in the environment can also significantly affect diamond wire cutting operations. High humidity can lead to the accumulation of moisture on the cutting wire, which may cause rusting or corrosion. This not only weakens the wire but can also lead to inconsistent cutting results. Furthermore, moisture can interact with the cutting fluids used during the process, potentially reducing their efficacy and leading to increased friction and heat generation. On the other hand, very low humidity can result in static electricity buildup, which can attract debris that interferes with the cutting process.

The presence of contaminants, such as dust, dirt, or other abrasive materials, can adversely affect diamond wire cutting. These substances can clog the diamond wire, leading to increased wear and tear and diminishing the cutting efficiency. Additionally, contaminants can introduce variability in the cutting process, resulting in uneven cuts and potential damage to both the wire and the material being cut. Ensuring a clean working environment is vital for maintaining optimal cutting performance.

The characteristics of the material being cut also interact with environmental conditions, influencing the diamond wire cutting process. For instance, softer materials may require different cutting parameters compared to harder materials. Environmental conditions can affect the hardness and structural integrity of certain materials, leading to variations in cutting speed and efficiency. Understanding how environmental factors impact material behavior is critical for optimizing the cutting process.

To mitigate the effects of environmental conditions on diamond wire cutting, regular maintenance and adaptation strategies should be implemented. This includes routinely checking the condition of the diamond wire, ensuring proper lubrication, and adjusting cutting speeds based on temperature and humidity levels. By being proactive in maintenance and adapting to changing environmental conditions, operators can enhance the performance and longevity of diamond wire cutting systems.

Recent advancements in technology have led to the development of more robust diamond wires and cutting systems that can better withstand adverse environmental conditions. Innovations such as improved coating technologies and enhanced diamond bonding techniques are helping to increase the durability and efficiency of diamond wire cutting. As research continues, we can expect further improvements that may allow for better performance under varied environmental conditions.

In conclusion, environmental conditions play a significant role in the effectiveness and efficiency of diamond wire cutting. Factors such as temperature, humidity, and the presence of contaminants can either enhance or hinder the cutting process. Understanding these influences allows operators to implement appropriate strategies for maintenance and adaptation, ultimately leading to improved performance and longer tool life. As technology continues to evolve, the industry can look forward to innovations that will further optimize diamond wire cutting in diverse environments.