Author:Huada Quarrying Machine FROM:Stone quarry machine manufacturer TIME:2024-11-04

In the world of stone fabrication, precision and efficiency are paramount. As the demand for thin stone slabs increases in various architectural and design applications, the methods used to cut these materials have evolved significantly. One innovative technology gaining traction is the use of diamond wire saws. This article will explore whether diamond wire can be effectively utilized for cutting thin stone slabs, examining its benefits, limitations, and practical applications.

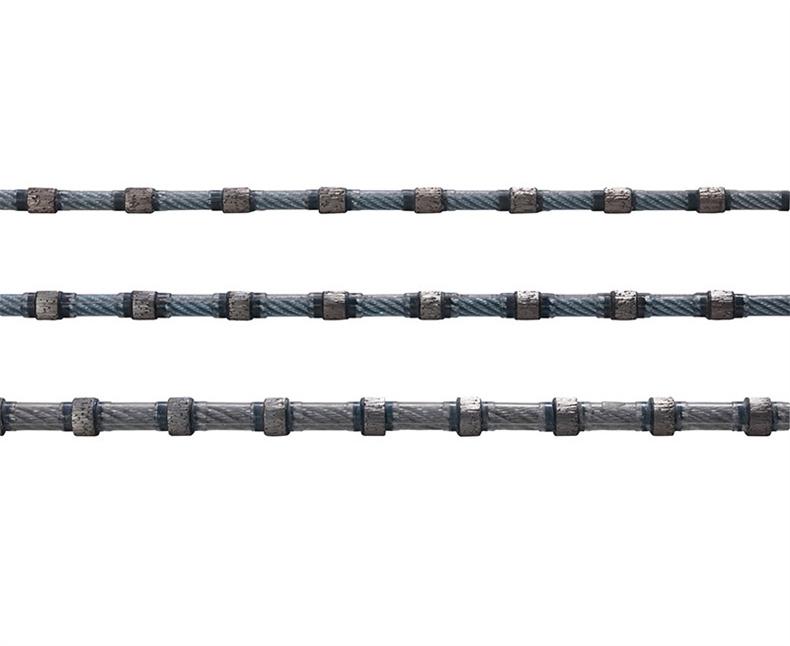

Diamond wire saws consist of a thin steel wire coated with diamond segments, which enable the cutting of hard materials such as stone and concrete. This technology offers several advantages over traditional cutting methods, including reduced waste, less energy consumption, and enhanced cutting speed. Understanding how diamond wire works provides insight into its application for thin stone slabs.

One of the primary benefits of using diamond wire for cutting thin stone slabs is precision. The thin profile of the wire minimizes kerf loss, allowing for more efficient use of materials. Additionally, diamond wire saws provide a smooth finish on the cut surface, reducing the need for further processing. This is particularly important when working with high-end designs where aesthetics are crucial.

Diamond wire saws generate significantly less waste compared to conventional saws. Traditional methods often result in larger amounts of stone being removed during the cutting process. In contrast, the thin wire creates narrow cuts, which means more usable material is left over. This efficiency not only saves costs but also aligns with increasing environmental concerns in the stone industry.

Another advantage of diamond wire saws is their versatility. They can efficiently cut through various types of stone, including granite, marble, and quartzite. This flexibility makes them an ideal choice for manufacturers who work with multiple stone varieties, as they can maintain consistent quality and precision regardless of the material being processed.

While there are numerous benefits, challenges exist when using diamond wire saws for thin stone slabs. One significant concern is the potential for wire breakage, especially when cutting very thin materials. Operators must carefully manage tension and speed to avoid damaging the wire or the slab. Additionally, the initial investment in diamond wire technology can be substantial, which may deter smaller businesses from adopting it.

The cost of diamond wire saws can be higher than traditional cutting methods, primarily due to the price of diamond segments and the specialized equipment required. However, this upfront investment can be offset by the long-term savings achieved through reduced material waste and faster production times. Companies must weigh these factors when deciding whether to transition to diamond wire technology.

Operator skill plays a crucial role in the successful use of diamond wire saws. Proper training and experience are necessary to maximize the benefits of this technology. Operators must understand the nuances of adjusting tension, feed rates, and cooling methods to prevent overheating and wire breakage. Investing in operator education can significantly enhance the effectiveness of diamond wire cutting processes.

As technology continues to advance, the diamond wire industry is evolving as well. Innovations in wire design, such as improved bonding techniques and new diamond coatings, are being developed to enhance performance. Additionally, integrating automation and robotics into the cutting process may increase efficiency and reduce labor costs. Staying informed about these trends is essential for businesses looking to remain competitive in the stone fabrication market.

Several stone manufacturers have successfully implemented diamond wire technology for cutting thin stone slabs. Case studies show that companies have reported increased production rates and improved product quality after transitioning to diamond wire saws. These examples highlight the potential for diamond wire technology to revolutionize stone cutting processes, making it a viable option for modern fabrication techniques.

In conclusion, diamond wire saws present a compelling solution for cutting thin stone slabs, offering numerous advantages such as precision, reduced waste, and versatility. Despite some challenges, including cost and the need for skilled operators, the benefits outweigh the drawbacks for many businesses. As technology progresses, we can expect even more advancements in diamond wire saw capabilities, further solidifying its role in the stone fabrication industry. For manufacturers looking to enhance their cutting processes, investing in diamond wire technology may be a strategic move towards efficiency and sustainability.