Author:Huada Quarrying Machine FROM:Stone quarry machine manufacturer TIME:2024-11-04

In the world of cutting tools, wire saws have emerged as a revolutionary alternative to traditional saws. While conventional saws such as band saws and circular saws have been widely used for decades, wire saw technology offers several advantages that make it a preferred choice in various industries. This article will explore the benefits of using wire saws over traditional saws, including their efficiency, precision, versatility, and safety features.

One of the most significant advantages of wire saws is their efficiency in cutting materials. Wire saws operate using a thin, flexible wire that is threaded through pulleys, allowing for continuous cutting action. This design enables them to cut through materials much faster compared to traditional saws. In applications where time is crucial, such as in manufacturing environments, the speed of wire saws can lead to increased productivity and reduced operational costs.

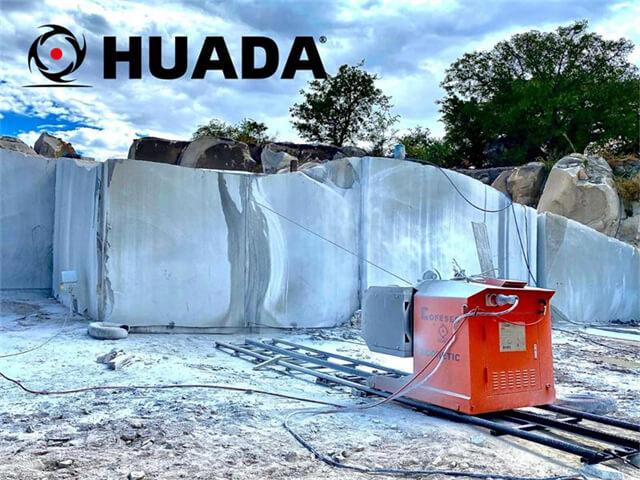

Wire saws provide exceptional precision and accuracy in cutting. The thin wire allows for narrow kerf cuts, which minimizes material wastage and ensures cleaner edges. This level of precision is particularly beneficial in industries that require intricate cuts, such as stone quarrying and advanced manufacturing. Traditional saws often leave rough edges that require additional finishing work, whereas wire saws can achieve the desired finish right from the cutting stage.

Another notable advantage of wire saws is their versatility. They can be used to cut a wide range of materials, including hard metals, ceramics, glass, and even stones. This adaptability makes wire saws suitable for various applications across different industries, from construction to electronics. Traditional saws often struggle with harder materials or require specific blades for different substances, making wire saws a more efficient solution for multi-material processing.

Using a wire saw also contributes to reduced waste and a lower environmental impact. The narrow kerf produced by wire saws results in less material being wasted during the cutting process. This not only saves money but also supports sustainability efforts in industries where material conservation is critical. As companies strive to minimize their environmental footprint, the adoption of wire saws aligns with eco-friendly practices.

Safety is a paramount concern in any industrial setting, and wire saws offer enhanced safety features compared to traditional saws. The design of wire saws allows for lower operating speeds, which reduces the risk of accidents and injuries. Additionally, the enclosed cutting mechanism minimizes exposure to moving parts, providing a safer working environment for operators. By reducing the potential for kickbacks and other hazards common with traditional saws, wire saws help improve overall workplace safety.

While the initial investment in a wire saw may be higher than that of traditional saws, they prove to be more cost-effective in the long run. The increased efficiency, reduced material waste, and lower maintenance costs associated with wire saws contribute to significant savings over time. Additionally, the durability of wire saws means they often have a longer lifespan compared to traditional options, further enhancing their cost-effectiveness.

Wire saws are generally easier to use and maintain compared to traditional saws. Their straightforward design means that operators can quickly learn how to operate them effectively, reducing training time. Maintenance is also simplified, as wire saws require less frequent blade changes and adjustments. This ease of use contributes to smoother operations and less downtime, further amplifying productivity in manufacturing processes.

In conclusion, the advantages of using wire saws over traditional saws are clear. Their efficiency, precision, versatility, and safety features make them a superior choice for many applications. As industries continue to evolve and seek out innovative solutions, wire saw technology stands out as a game-changer in cutting processes. By embracing this modern cutting technology, companies can enhance their productivity, reduce costs, and improve overall safety in their operations.