Author:Huada Quarrying Machine FROM:Stone quarry machine manufacturer TIME:2024-11-14

Diamond wire cutting technology has revolutionized various industries, particularly in masonry applications. This innovative method utilizes a wire embedded with diamond segments, offering enhanced precision, speed, and efficiency compared to traditional cutting methods. As the demand for high-quality masonry work continues to rise, understanding the capabilities and benefits of diamond wire in this field becomes increasingly important. This article explores whether diamond wire can be effectively used for masonry applications, examining its advantages, potential challenges, and best practices.

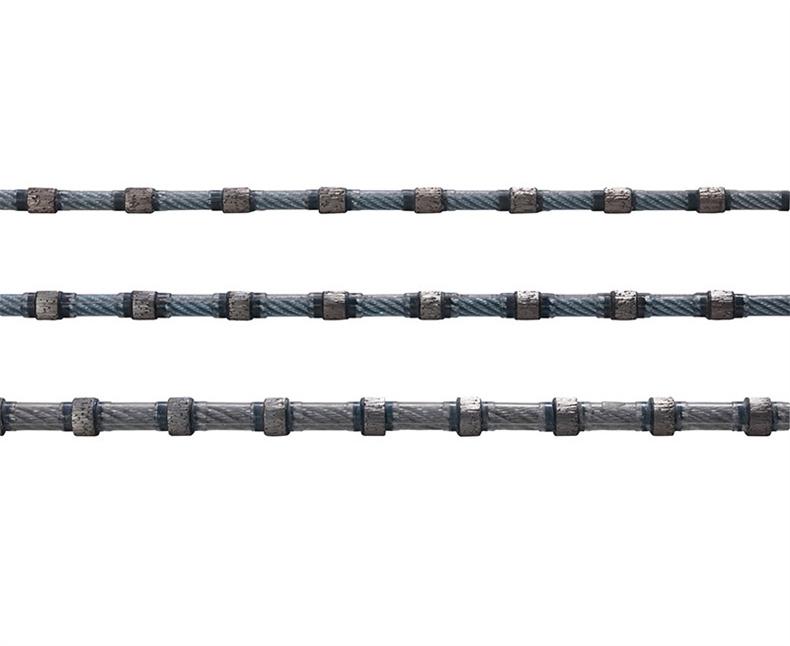

Diamond wire cutting involves the use of a steel wire that is threaded through a series of pulleys and connected to a cutting machine. The wire is coated with diamond particles, which are incredibly hard and provide superior cutting ability. This technology is widely used in industries such as stone processing, concrete cutting, and even in the manufacturing of advanced materials. Its application in masonry is gaining traction due to the need for precise and clean cuts.

The primary advantage of using diamond wire for masonry work is its ability to make clean and precise cuts. Unlike traditional saws that may cause chipping or cracking, diamond wire minimizes damage to the material being cut. This is particularly beneficial when working with delicate stones or bricks where aesthetics are crucial. Additionally, diamond wire cutting is faster than conventional methods, reducing labor time and improving overall project efficiency.

Diamond wire is highly versatile and can be used on a wide range of masonry materials including brick, concrete, granite, and limestone. This adaptability makes it an excellent choice for contractors who frequently work with different types of stone or masonry products. By utilizing diamond wire, contractors can streamline their operations, as they won’t need to switch tools for different materials. This versatility also allows for more creative architectural designs, as intricate shapes and cuts become easier to achieve.

Safety is a paramount concern in any construction environment. Diamond wire cutting systems tend to have lower vibration levels compared to traditional saws, which enhances operator comfort and reduces the risk of injury. Furthermore, the enclosed nature of diamond wire machines helps to contain dust and debris, contributing to a safer job site. The reduction in noise levels is another advantage, making it a more pleasant working environment for contractors and clients alike.

While the initial investment in diamond wire cutting equipment may be higher than traditional methods, the long-term savings can be significant. The speed and efficiency of diamond wire cutting can lead to reduced labor costs and faster project completion times. Moreover, the precision of the cuts minimizes waste, allowing for better utilization of materials. This cost-effectiveness makes diamond wire a practical choice for both small and large masonry projects.

Despite its many advantages, there are challenges to consider when using diamond wire for masonry applications. One key consideration is the need for specialized training to operate the machinery effectively. Operators must understand how to adjust the tension and speed of the wire according to the material being cut. Additionally, although diamond wire is durable, it can wear out over time and require replacement, which adds to maintenance costs.

To maximize the benefits of diamond wire cutting in masonry, several best practices should be followed. First, operators should regularly inspect the diamond wire for signs of wear and replace it as needed to maintain cutting efficiency. Proper training is essential to ensure that all team members are familiar with the equipment and techniques required for optimal performance. Additionally, using the appropriate type of diamond wire for specific materials will enhance cutting quality and prolong the lifespan of the wire.

The future of diamond wire technology in masonry applications looks promising. Innovations are continually emerging, including advancements in diamond coating techniques that improve cutting efficiency and longevity. Additionally, the integration of automation and robotics in diamond wire cutting processes may further enhance precision and reduce labor requirements. As the technology evolves, its adoption in the masonry sector is likely to increase, providing even greater opportunities for builders and contractors.

In conclusion, diamond wire cutting technology is an effective and efficient solution for masonry applications. Its advantages, including precision, speed, safety, and versatility, make it a valuable tool for contractors and builders. While there are challenges associated with its use, proper training and adherence to best practices can mitigate these issues. As the industry continues to evolve, the integration of diamond wire technology is set to redefine standards in masonry work, paving the way for innovative construction techniques and design possibilities.