Author:Huada Quarrying Machine FROM:Stone quarry machine manufacturer TIME:2024-10-31

A wire saw machine is a sophisticated tool that is widely used in various industries, particularly in stone cutting, metal fabrication, and even in the semiconductor sector. Its design and functionality allow for precise cutting with minimal waste, making it an essential equipment for many manufacturing processes. This article will explore how a wire saw machine works, detailing its components, operational principles, and applications.

The wire saw machine consists of several key components that work together to facilitate efficient cutting. The primary components include the wire, the drive system, the tensioning mechanism, and the cutting head. The wire is typically made of high-strength steel or diamond-coated material, allowing it to cut through hard materials like granite or metal with ease.

The drive system powers the movement of the wire, rotating it at high speeds. This can involve electric motors or hydraulic systems, depending on the machine's design and intended use. The tensioning mechanism ensures that the wire remains taut during operation, which is critical for achieving accurate and clean cuts. Finally, the cutting head holds the wire in place and guides it through the material being cut.

The operation of a wire saw machine involves several steps. First, the wire is threaded through the cutting head and secured in place. Once set up, the machine is powered on, and the drive system begins to rotate the wire at high speed. This rotation creates a frictional force against the material being cut, allowing the wire to slice through it effectively.

The operator can control the speed and tension of the wire, adjusting these parameters based on the material's hardness and thickness. By maintaining optimal tension and speed, the machine can achieve a smooth cut while minimizing wear on the wire itself. Additionally, some advanced wire saw machines are equipped with cooling systems to reduce heat generated during cutting, further extending the wire's lifespan.

The choice of wire is crucial in determining the efficiency and quality of the cut. There are primarily two types of wire used in wire saw machines: steel wire and diamond wire. Steel wire is often used for softer materials and provides good durability and cost-effectiveness. On the other hand, diamond wire incorporates industrial-grade diamonds bonded to the wire, making it suitable for cutting harder materials like granite, marble, and concrete.

Diamond wire saws are particularly popular in the stone industry due to their ability to produce clean cuts with minimal chipping. The selection of the appropriate wire type depends on the specific requirements of the cutting job, including the material’s properties and the desired finish.

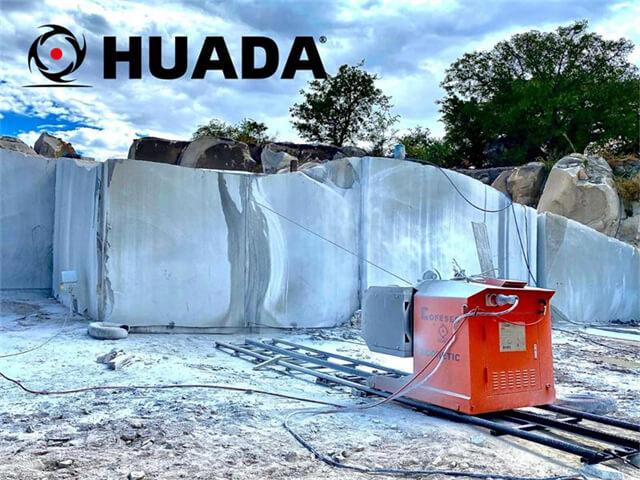

Wire saw machines have a wide range of applications across various industries. In the stone industry, they are primarily used for cutting blocks of granite and marble into slabs for countertops, tiles, and monuments. Their precision reduces waste, allowing manufacturers to maximize their raw materials.

In addition to stone cutting, wire saws are also employed in metal fabrication. They can cut through thick metal sheets, making them invaluable in automotive and aerospace manufacturing. Furthermore, in the semiconductor industry, wire saw machines are used to slice silicon wafers with extreme precision, ensuring the quality and performance of electronic components.

The advantages of wire saw machines are significant compared to traditional cutting methods. One of the most notable benefits is the ability to produce cleaner cuts with less material loss. This efficiency translates to cost savings for manufacturers, as they can utilize more of their raw materials.

Additionally, wire saw machines can operate at high speeds, increasing production rates. The reduced wear on the cutting wire also leads to lower maintenance costs and less frequent replacements. Moreover, wire saws generate less vibration and noise during operation, contributing to a safer and more pleasant working environment.

Despite their many benefits, wire saw machines come with challenges. One significant consideration is the initial investment cost, which can be higher than traditional saws. Additionally, operators must be trained to handle the equipment properly and maintain the wire saw to ensure optimal performance.

Another challenge is the requirement for regular maintenance and monitoring of the wire. Factors such as the material being cut and the operating conditions can lead to varying levels of wear on the wire, necessitating timely replacements to avoid downtime in production.

The future of wire saw technology looks promising, with advancements aimed at improving efficiency and capabilities. Innovations in materials science may lead to the development of even more durable wires, capable of handling tougher materials and higher speeds. Additionally, automation and smart technology integration could enhance operational efficiency, allowing for real-time monitoring and adjustments during cutting processes.

Furthermore, as industries continue to focus on sustainability, wire saw machines may evolve to minimize energy consumption and waste, aligning with global environmental goals. These advancements will likely expand the applications of wire saw technology, making it an integral part of modern manufacturing processes.

In summary, wire saw machines represent a significant advancement in cutting technology, offering precision and efficiency across various industries. Their unique operational mechanisms, combined with the versatility in wire selection and application, make them indispensable tools for manufacturers. While challenges such as initial costs and maintenance exist, the benefits far outweigh these drawbacks. As technology continues to evolve, wire saw machines will undoubtedly play an even more critical role in shaping the future of manufacturing.