Author:Huada Quarrying Machine FROM:Stone quarry machine manufacturer TIME:2023-09-15

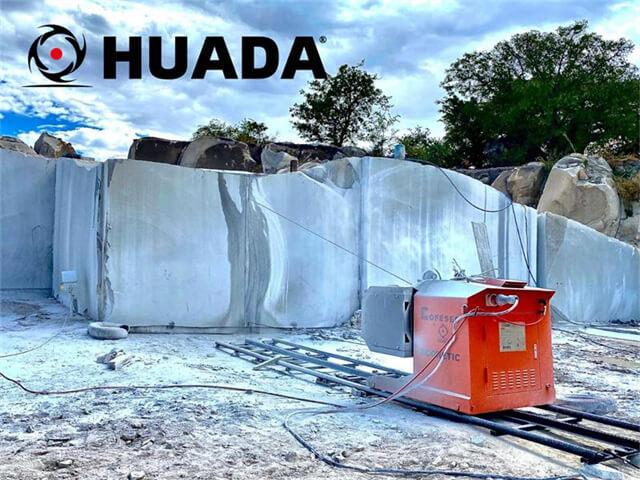

Diamond wire saw machine technology is an advanced cutting method used in various industries, such as construction, mining, and stone processing. This article aims to provide an overview of the technical features of diamond wire saw machine technology, highlighting its benefits and applications.

The diamond wire saw machine offers high cutting efficiency due to the use of a thin, flexible wire embedded with diamond beads. These diamond beads are designed to continuously cut through the material, enabling faster and more precise cutting. Compared to traditional cutting methods, such as saw blades or discs, the diamond wire saw machine can significantly increase productivity and reduce labor costs.

One of the key advantages of diamond wire saw machine technology is its versatility. It can be used to cut various materials, including concrete, reinforced concrete, granite, marble, and even metal. This versatility makes it an ideal tool for a wide range of applications, from demolition and construction to mining and stone processing.

Diamond wire saw machines allow for precise cutting with minimal material loss and damage. The thin diamond wire cuts through the material with high accuracy, resulting in clean, straight cuts. This precision cutting capability is essential in industries where accuracy is critical, such as in the fabrication of intricate stone sculptures or the production of high-quality construction materials.

Unlike traditional cutting methods that often produce significant vibrations, diamond wire saw machines generate minimal vibrations during operation. This is due to the smooth and continuous cutting action of the wire, which reduces the impact on the surrounding structure and minimizes the risk of damage. Reduced vibrations also contribute to a safer and more comfortable working environment for operators.

Many diamond wire saw machines are equipped with remote operation capabilities, allowing operators to control the cutting process from a safe distance. This feature is particularly beneficial in hazardous or hard-to-reach locations, as it eliminates the need for operators to be physically present near the cutting site. Remote operation not only enhances safety but also increases efficiency by reducing downtime for setup and repositioning.

The diamond wire saw machine enables continuous cutting without the need for frequent interruptions, such as blade changes or coolant replenishment. The diamond beads on the wire can last for a long time before needing replacement, providing uninterrupted cutting for extended periods. This feature is highly advantageous in large-scale projects where efficiency and productivity are paramount.

In conclusion, diamond wire saw machine technology offers several technical features that make it a preferred cutting method in various industries. Its high cutting efficiency, versatility, precision cutting, reduced vibrations, remote operation, and continuous cutting capabilities contribute to increased productivity, improved safety, and cost savings. As technology continues to advance, we can expect further enhancements and innovations in diamond wire saw machine technology, making it an indispensable tool for the future.