Author:Huada Quarrying Machine FROM:Stone quarry machine manufacturer TIME:2023-06-06

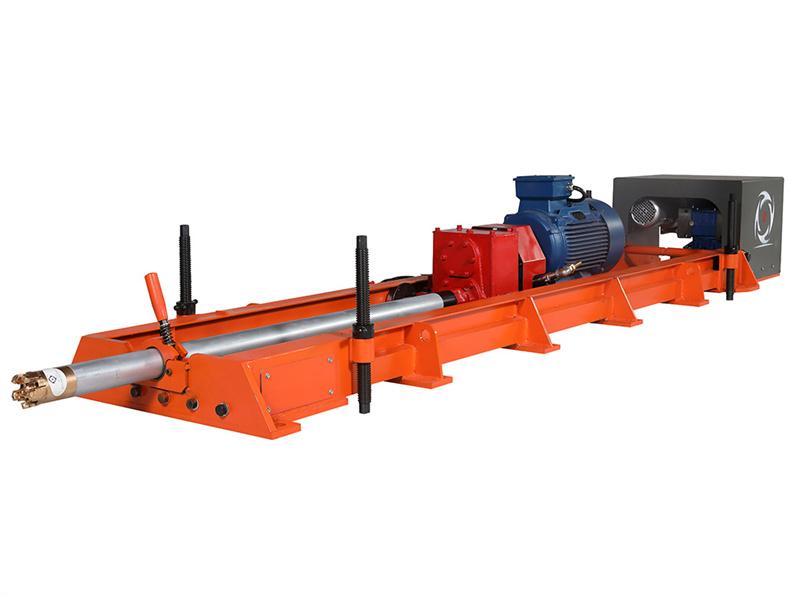

Horizontal core boring machine are commonly used mechanical equipment in various mines such as geological prospecting, concrete engineering, and petroleum and stone. In stone mining, horizontal drilling rigs are often used in conjunction with diamond wire saws. So which type of drill bit is more appropriate when using a horizontal core boring machine?

What are the drill bits for horizontal core boring machine?

Generally speaking, the drill bits used in horizontal core boring machine are divided into two categories, one is core drills and the other is coreless drills. The coreless bit will break the stone directly when drilling. The core bit is also called the hollow bit; because the middle part of the core bit is hollow, the stone will stay inside the bit when drilling, and it needs to be done at the end of the drilling.

Application of coreless bit and core bit

The coreless drill bit is suitable for the stone with lower hardness. For this kind of stone, the drilling speed is faster with the coreless drill bit; the core drill bit is used for the stone with higher hardness of the stone. The contact area is only one outer circle, so the drilling efficiency is higher and the cost is lower.

For more information about stone mining equipment, welcome to visit the official website of Huada.