Author:Huada Quarrying Machine FROM:Stone quarry machine manufacturer TIME:2023-06-06

Circular saw unidirectional vertical sawing refers to the double saw blade cutting machine sawing the ore body into comb shaped long blocks along the length direction of the working line, i.e. X direction.

In the unidirectional vertical sawing separation process, the circular saw is usually used to cut the ore body vertically downward along the X direction parallel to the working line. If the vertical section is the main section, the sawing gap can be equal to the thickness of 1 or 2 blocks; If the horizontal plane is the main section of the raw material, the saw joint spacing is equal to the height dimension of the raw material.

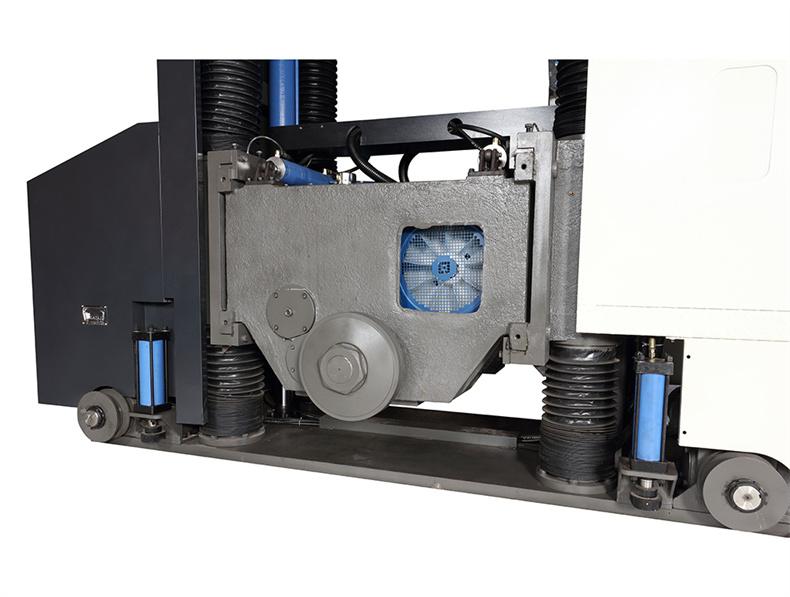

When using a single blade circular saw, moving the saw guide rail can adjust the spacing of comb parallel planes; When using double blade circular saw, the adjustment range of saw blade spacing of saw machine shall meet the requirements of comb parallel plane spacing adjustment.

The cutting depth of double saw blade cutting machine is related to the diameter of saw blade. Generally, when hierarchical sawing is adopted, the final cutting depth is reached. The diameter of the front saw blade is small and the thickness of the cutter head is large. The diameter of the subsequent saw blade increases step by step and the thickness of the cutter head decreases step by step, so that the subsequent saw blade can cut into the front saw slot smoothly.

If a single circular saw is used, the final cutting depth is usually achieved by replacing saw blades with different diameters and sawing in groups of 2 or 3 times.

2 ~ 3 circular saws with different diameter blades can also be used to achieve the final cutting depth by combined connection. When the circular saw needs to be replaced to the new cutting position, the transition track (also known as rail crossing or ferry Guide) temporarily connecting the two X-direction tracks shall be installed in the Y direction to move the circular saw to the new cutting track.

According to the final sawing depth, the diameter of the first stage saw blade is 1.6 ~ 2.6m, the diameter of the middle stage saw blade is 2.6 ~ 3.6m, and the diameter of the final stage saw blade is 3.6 ~ 4.8m. At present, the maximum diameter of the saw blade of the double saw blade cutting machine for granite and marble mines is 4.8m, which can meet the requirements of 2m vertical cutting depth (main cutting surface of waste material).