Author:Huada Quarrying Machine FROM:Stone quarry machine manufacturer TIME:2025-01-20

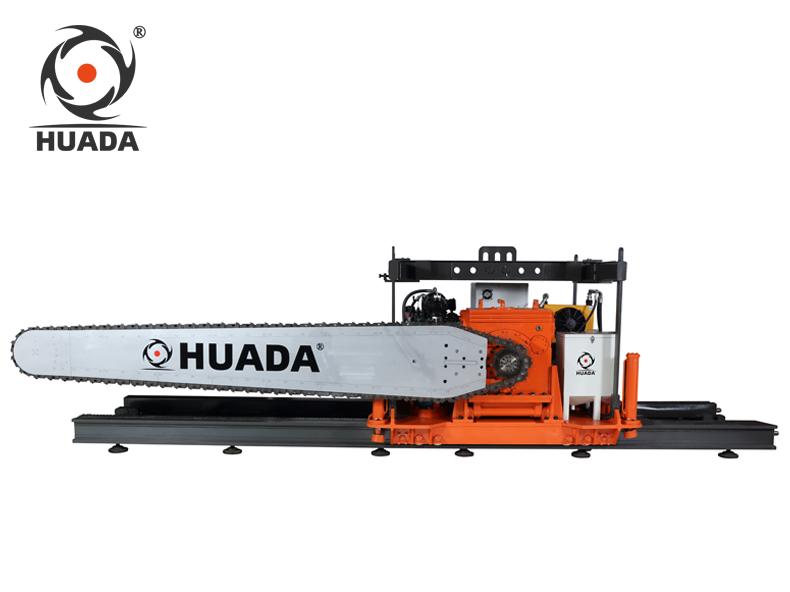

When it comes to construction and landscaping, stone chain saw machines play a crucial role in cutting and shaping hard materials like granite and marble. However, one significant concern associated with their use is the noise level they produce. Understanding the noise levels of these machines is essential for ensuring compliance with regulations, protecting workers’ hearing, and maintaining a peaceful environment in residential areas. This article delves into the noise levels of typical stone chain saw machines, factors affecting these levels, and best practices for noise management.

Noise levels are measured in decibels (dB), a logarithmic unit that quantifies sound intensity. For context, normal conversation occurs at around 60 dB, while sounds above 85 dB can potentially cause hearing damage with prolonged exposure. Stone chain saw machines typically operate at noise levels ranging from 90 to 110 dB, depending on their design and usage conditions. This makes them considerably louder than everyday sounds, necessitating protective measures for operators and bystanders alike.

The noise produced by stone chain saw machines can vary widely based on several factors. The type of machine, its motor power, blade design, and even the material being cut can all influence the overall noise output. For instance, a more powerful machine might generate higher noise levels due to increased motor activity and faster cutting speeds. Additionally, different types of blades can create varying levels of noise depending on their material composition and cutting efficiency.

To better understand the noise levels of stone chain saw machines, it’s helpful to compare them with other common tools used in construction and landscaping. For example, a standard chainsaw operates at approximately 100 dB, while a jackhammer can exceed 120 dB. In comparison, stone chain saws fall within a similar range as these tools but may be perceived as less disruptive due to their specific applications in cutting stone rather than general construction work.

Extended exposure to high noise levels, such as those generated by stone chain saw machines, can lead to various health issues, particularly hearing loss. The Occupational Safety and Health Administration (OSHA) sets permissible noise exposure limits, and employers must take steps to mitigate risks. Continuous exposure to sounds above 85 dB can cause permanent hearing loss, making it crucial for operators to use appropriate personal protective equipment (PPE), such as earplugs or earmuffs, during operation.

In many regions, regulatory bodies have established noise control regulations to protect workers and surrounding communities from excessive noise pollution. Employers using stone chain saw machines must comply with these regulations, which often include monitoring noise levels and implementing engineering controls to reduce sound output. Compliance not only protects employees but also helps businesses avoid legal penalties and maintain a positive relationship with the community.

There are several strategies that can be employed to mitigate the noise produced by stone chain saw machines. One effective method is to utilize sound barriers or enclosures during operation. These barriers can absorb and deflect sound waves, reducing the overall noise level experienced in surrounding areas. Additionally, regular maintenance and servicing of machines can help ensure they operate efficiently and quietly, further minimizing noise output.

Advancements in technology have led to the development of quieter stone chain saw machines. Manufacturers are increasingly focusing on creating designs that minimize noise without sacrificing performance. Innovations such as improved motor designs, vibration dampening systems, and specialized cutting blades contribute to lower noise levels, making these machines more user-friendly and compliant with noise regulations.

For operators of stone chain saw machines, adhering to best practices can significantly reduce exposure to harmful noise levels. This includes wearing proper hearing protection at all times, scheduling breaks to limit continuous exposure, and ensuring proper training on the safe use of equipment. Operators should also remain aware of their surroundings and implement noise reduction strategies whenever possible to maintain a safe working environment.

In summary, the noise level of typical stone chain saw machines presents significant considerations for both operators and the surrounding community. Operating at noise levels between 90 and 110 dB, these machines can pose risks to hearing and contribute to environmental noise pollution. By understanding the factors influencing noise levels, adhering to regulatory standards, and employing effective noise mitigation strategies, businesses can create a safer and more compliant working environment. As technology continues to advance, the industry is likely to see further improvements in the design and operation of stone chain saw machines, leading to enhanced performance and reduced noise output in the future.