Author:Huada Quarrying Machine FROM:Stone quarry machine manufacturer TIME:2025-01-19

When it comes to cutting stone, two popular types of machines stand out: pneumatic stone chain saws and electric stone chain saws. Both have their unique advantages and applications, making them suitable for different tasks in the stone industry. This article will explore the key differences between these two machines, examining their operational mechanisms, efficiency, applications, and maintenance requirements.

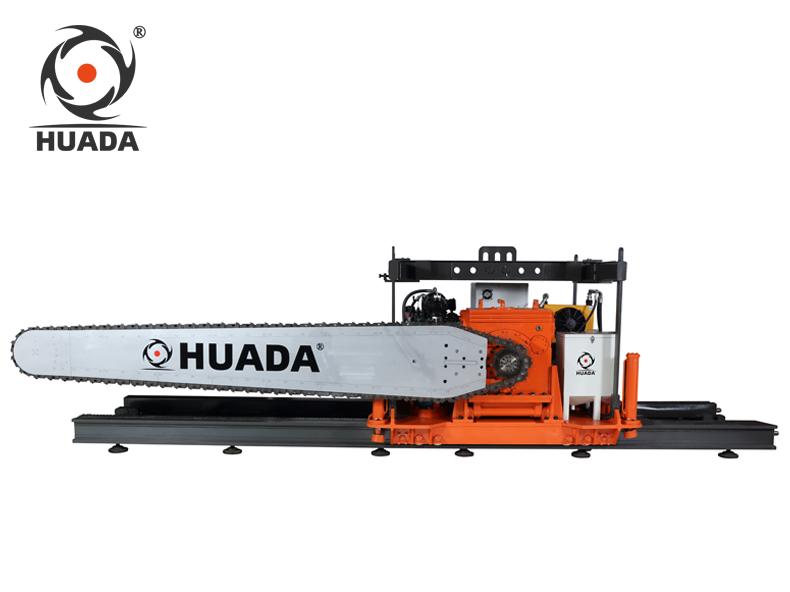

Pneumatic stone chain saw machines operate using compressed air to power their cutting action. This method allows for a lightweight design and the ability to work in environments where electricity may not be readily available. The air compressor generates high pressure, which is then directed to the saw, enabling it to cut through tough stone materials effectively. This system offers significant mobility and flexibility, particularly on job sites that require frequent relocation.

In contrast, electric stone chain saws use electric motors to drive the cutting chain. These machines typically offer more consistent power output compared to their pneumatic counterparts. Electric saws can be plugged into a power source, ensuring continuous operation without the need for external air compressors. They are often favored for indoor applications or locations where electrical capabilities are easily accessible.

When assessing efficiency, both pneumatic and electric stone chain saws have distinct characteristics. Pneumatic machines are generally lighter and easier to maneuver, which can enhance productivity in certain environments. Their ability to operate in remote areas without electricity can also make them more versatile in some scenarios. However, they may require more effort to maintain a constant cutting speed due to variations in air pressure.

Electric stone chain saws, on the other hand, provide a steady and reliable power supply. This stability contributes to a more uniform cutting performance, especially in challenging materials. Electric models are often equipped with advanced features such as variable speed controls, allowing operators to adjust the cutting speed according to the material being worked on. This adaptability can lead to more efficient cutting and reduced wear on the equipment.

The applications for pneumatic and electric stone chain saws differ significantly based on their operational characteristics. Pneumatic saws are commonly used in outdoor settings or remote locations where electricity is unavailable. They excel in quarrying and heavy-duty cutting tasks, where mobility and the ability to handle large blocks of stone are essential. Their lightweight nature makes them ideal for extended use without causing operator fatigue.

Electric stone chain saws find their niche in indoor settings, such as workshops or construction sites with reliable power sources. They are particularly effective for detailed work and precision cuts, making them the preferred choice for artisans and stone masons who focus on intricate designs. Additionally, electric models tend to produce less noise and vibration, contributing to a more comfortable working environment.

Maintenance is a critical aspect of any machinery, and both pneumatic and electric stone chain saws have specific needs. Pneumatic machines often require regular checks of the air compressor and hoses to ensure optimal performance. Operators must monitor air pressure levels and perform routine lubrication of moving parts to prevent wear and tear. This can entail more frequent maintenance due to the complexity of the air system.

Electric stone chain saws typically necessitate less maintenance. However, users should regularly inspect the electrical components, such as wiring and connections, to prevent electrical failures. Blade sharpness is crucial for both types of saws, and operators should ensure that blades are sharpened or replaced as needed to maintain cutting efficiency. Overall, while pneumatic saws may demand more comprehensive upkeep, electric saws require consistent attention to their electrical systems.

Cost is another factor to consider when choosing between pneumatic and electric stone chain saws. Pneumatic machines may have a lower initial purchase price, but the requirement for an air compressor and the associated costs can add up. Additionally, ongoing operational costs, such as air consumption and maintenance, can impact the overall expense.

On the other hand, electric stone chain saws may come with a higher upfront cost, particularly if they include advanced features. However, the lack of additional equipment, such as compressors, often makes them more economical over time. Electric models can also boast lower energy costs, especially if used in environments where electricity is readily available and affordable.

In today’s world, environmental considerations play a crucial role in equipment selection. Pneumatic stone chain saws generally have a larger carbon footprint due to their reliance on compressed air systems, which often consume more energy. Additionally, the noise generated by these machines can contribute to environmental pollution, particularly in residential areas.

Conversely, electric stone chain saws are usually quieter and produce no emissions during operation, making them a more environmentally friendly choice. This aspect is particularly important in urban settings where noise ordinances and air quality regulations are in place. As sustainability becomes increasingly important in construction and manufacturing, the preference for electric models may rise.

In summary, the choice between pneumatic and electric stone chain saw machines ultimately depends on the specific needs of the user. Pneumatic saws offer flexibility and mobility, making them ideal for outdoor and remote operations, while electric saws provide consistent power and efficiency for indoor applications. Understanding the differences in operational mechanisms, efficiency, applications, maintenance requirements, cost considerations, and environmental impact can help operators make informed decisions that best suit their projects. Whether one opts for pneumatic or electric technology, each machine plays a vital role in the stone-cutting industry, enhancing productivity and enabling precise craftsmanship.