Author:Huada Quarrying Machine FROM:Stone quarry machine manufacturer TIME:2025-01-18

Transporting a stone chain saw machine requires careful planning and execution to ensure safety and efficiency. These machines are essential for cutting stone in various applications, from quarrying to construction. However, their weight, size, and delicate components make transportation a critical aspect that must be handled with care. This article discusses the best methods to transport a stone chain saw machine, focusing on preparation, packaging, loading, and safety considerations. By following these guidelines, you can facilitate a smooth transportation process and minimize the risks of damage.

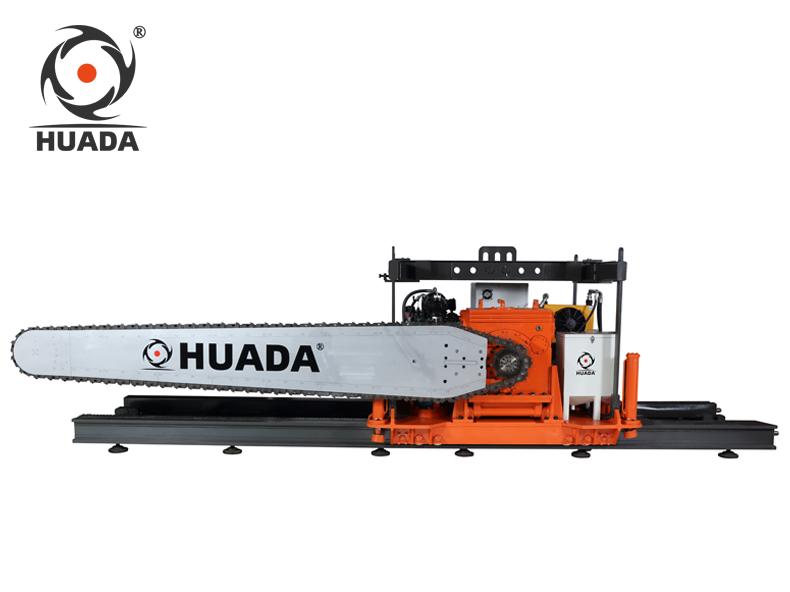

Before delving into transportation methods, it is essential to understand the stone chain saw machine's structure and functionality. These machines typically consist of a powerful motor, a chain with cutting teeth, and a guide bar. They are designed to cut through hard materials such as granite and marble, making them valuable tools in the stone industry. Their robust design means they can be quite heavy, often weighing several hundred pounds. This weight necessitates special attention during transportation to prevent injury or equipment damage.

Proper preparation is crucial before transporting a stone chain saw machine. Start by reviewing the manufacturer's instructions or guidelines related to transportation. This can include information on disassembling parts or securing components. Ensure that all loose parts, such as chains and protective covers, are removed or secured appropriately. Additionally, perform a thorough inspection to identify any existing issues that may worsen during transport. Addressing these problems beforehand can save time and costs later.

Selecting an appropriate vehicle for transportation is vital for ensuring the machine's safety. Depending on the size and weight of the stone chain saw machine, options may include flatbed trucks, trailers, or enclosed vans. Flatbed trucks are often preferred for larger machines due to their open design, allowing for easy loading and unloading. However, if the weather or road conditions pose a risk, an enclosed vehicle can offer added protection. Always check the vehicle's load capacity to ensure it can support the machine's weight.

Proper packaging plays a significant role in protecting the stone chain saw machine during transport. Use sturdy materials such as plywood for crates or pallets to create a stable base for the machine. Ensure that the machine is securely fastened to the packaging to prevent any movement during transit. Use padding materials such as foam or blankets around the machine to absorb shocks and vibrations. If possible, disassemble larger components to make the machine more manageable and reduce the risk of damage.

Loading the stone chain saw machine onto the transport vehicle requires careful technique to avoid accidents. Utilize ramps or hoists to assist with the loading process, particularly for heavier machines. Ensure that the loading area is clear and that you have enough personnel to help with the lift. When positioning the machine on the vehicle, place it centrally to maintain balance during transport. Secure the machine using straps or chains to prevent shifting or tipping over while on the road.

Once loaded, securing the stone chain saw machine is paramount. Use high-quality ratchet straps or chains to tightly secure the machine to the vehicle. Make sure to check that the straps are not too loose or too tight, as this can cause damage during transit. Additionally, consider using wheel chocks to prevent any movement from the wheels of the machine. Regularly check the security of the load during transportation, especially if traveling long distances.

Safety should always be a top priority when transporting heavy machinery. Ensure that all personnel involved in the loading and unloading processes wear appropriate personal protective equipment (PPE), such as gloves, helmets, and steel-toed boots. Follow all local regulations regarding transportation of heavy equipment, including necessary permits or signage. Ideally, choose routes that avoid steep hills or sharp turns, which can pose challenges when transporting heavy loads.

Unloading the stone chain saw machine requires just as much care as loading it. Use ramps or cranes to lower the machine safely onto the ground. Have a plan in place for how the machine will be moved once unloaded, ensuring that the area is clear of obstacles. Again, ensure that all personnel involved in the unloading process are equipped with PPE and follow safety protocols. Take your time to avoid rushing, which can lead to accidents.

After transporting the stone chain saw machine, conduct a thorough inspection before putting it back into operation. Check for any signs of wear or damage that may have occurred during transport. Inspect the blade and chain for any misalignment or damage, and ensure that all components are functioning correctly. Address any issues immediately to prevent further complications during use.

In conclusion, transporting a stone chain saw machine requires meticulous planning and execution to ensure safety and prevent damage. Understanding the machine, preparing adequately, selecting the right vehicle, and employing proper loading and securing techniques are all critical steps in the process. With careful attention to detail and adherence to best practices, you can successfully transport a stone chain saw machine and maintain its functionality for future use. Always prioritize safety for yourself and others involved in the transportation process, as this will contribute to a successful operation overall.