Author:Huada Quarrying Machine FROM:Stone quarry machine manufacturer TIME:2025-01-15

Diamond saw blades are specialized cutting tools used in various industries for their efficiency and precision. These blades are embedded with diamond particles, which allow them to cut through hard materials that traditional blades cannot handle. This article explores the different types and applications of diamond saw blades, shedding light on their importance in construction, manufacturing, and other fields. Understanding what a diamond saw blade is used for can help professionals select the right tool for their specific needs.

In the construction industry, diamond saw blades are widely used for cutting concrete, asphalt, brick, and stone. Their ability to cut through dense materials makes them ideal for tasks such as road construction and building renovations. For instance, when workers need to create expansion joints in concrete slabs or cut through thick asphalt during resurfacing projects, diamond blades provide fast and clean cuts while minimizing dust and debris. Additionally, these blades can handle heavy-duty equipment, making them essential for demolition work where precise cuts are necessary to ensure safety and efficiency.

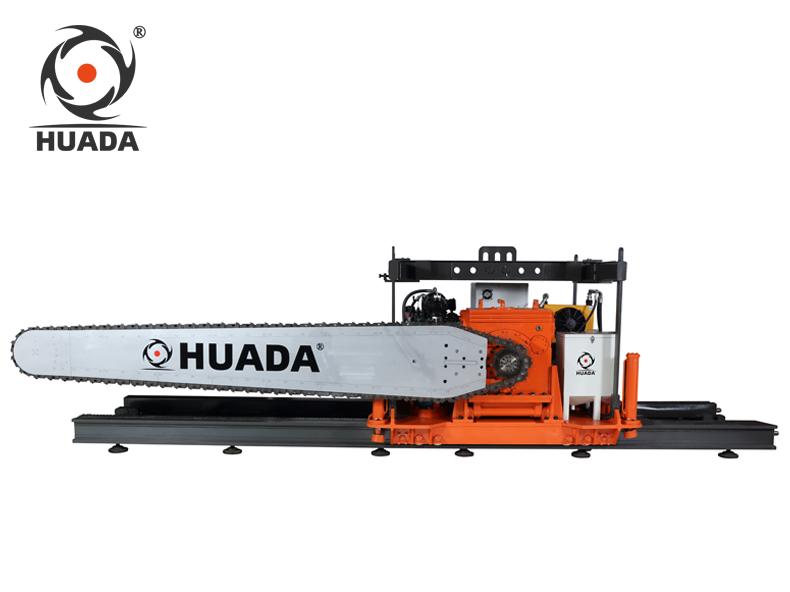

Diamond saw blades are particularly favored in stone and masonry applications. They are designed to cut through granite, marble, limestone, and other natural stones with ease. The use of diamond blades ensures that the cuts are smooth and precise, which is crucial for creating countertops, tiles, and sculptures. In masonry, these blades help craftsmen achieve intricate designs without chipping or damaging the stone. The versatility of diamond blades allows for both straight cuts and curved cuts, making them indispensable tools for stonemasons and tile setters.

While primarily associated with cutting hard materials like stone and concrete, diamond saw blades are also effective for certain metal cutting applications. Blades designed for cutting ferrous and non-ferrous metals feature specialized diamond segments that maintain the edge needed for clean cuts. These blades can be used in fabricating metal structures, cutting pipes, and performing tasks in manufacturing industries. Using diamond blades for metal cutting can enhance productivity, as they often require less frequent sharpening compared to traditional metal cutting blades.

In the tile and ceramics industry, diamond saw blades play a crucial role in ensuring high-quality finishes. These blades are essential for cutting porcelain tiles, ceramic tiles, and glass mosaics, allowing installers to achieve precise measurements and angles. The fine diamond particles help reduce the risk of chipping, which is vital in maintaining the aesthetic integrity of the tiles. Additionally, wet-cutting techniques using water with diamond blades minimize dust and heat, further protecting the integrity of both the blade and the material being cut.

Diamond saw blades are specifically engineered for cutting asphalt, which presents unique challenges due to its soft and sticky nature. These blades feature a high diamond concentration and specific bond formulations that enable them to cut through asphalt smoothly and efficiently. Whether for road repairs, trenching, or utility installations, diamond blades help contractors complete asphalt cutting jobs quickly, reducing downtime and improving overall project timelines.

In manufacturing settings, diamond saw blades are integral to the fabrication processes of various materials. From cutting composite materials to slicing through advanced ceramics, these blades provide the precision required in high-tech manufacturing environments. Companies benefit from using diamond blades due to their longevity and the quality of the cuts they produce, which lead to reduced waste and improved product consistency. This is particularly important in industries where tolerances are tight and quality assurance is paramount.

The advantages of diamond saw blades extend beyond just their cutting capabilities. They offer several benefits that make them favorable over traditional blades. One significant advantage is their durability; diamond blades can last much longer than standard steel blades, reducing the frequency of replacements and maintenance costs. Additionally, they provide cleaner cuts with minimal chipping or fracturing, which is especially important in industries where aesthetics matter. Lastly, diamond blades operate more efficiently, often requiring less force and energy to make cuts, leading to reduced wear on machinery and lower operational costs.

In summary, diamond saw blades are essential tools across multiple industries, including construction, masonry, metalworking, and manufacturing. Their ability to cut through hard materials with precision and efficiency makes them invaluable for professionals seeking quality results. As technology advances, the design and application of diamond saw blades continue to evolve, further enhancing their functionality and effectiveness. Understanding the various uses and benefits of diamond saw blades can help users make informed choices, leading to improved productivity and successful project outcomes.