Author:Huada Quarrying Machine FROM:Stone quarry machine manufacturer TIME:2025-01-14

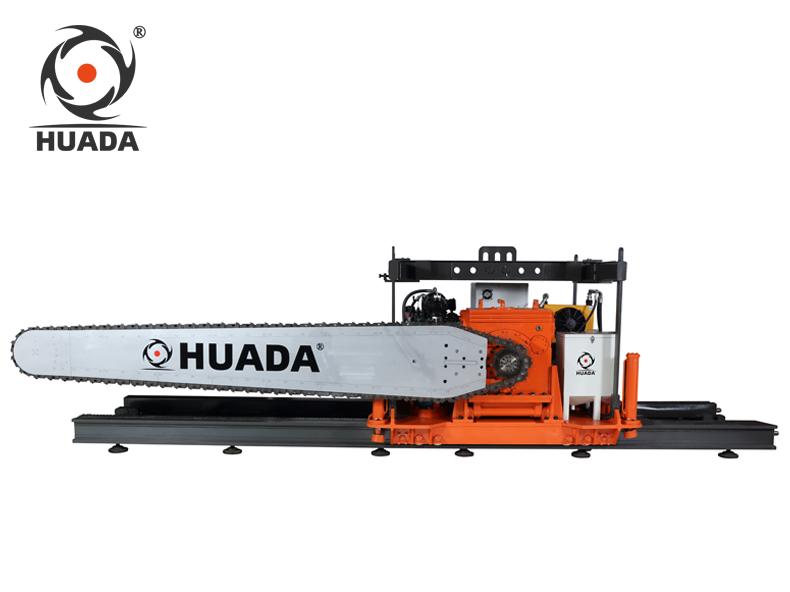

Stone chain saw machines have become essential tools in the stone quarrying and processing industries. These machines offer efficiency and precision in cutting stone, which is vital for various applications including construction, sculpture, and monument creation. Understanding the main components of a stone chain saw machine can help users optimize its performance and maintenance. This article will delve into the key components that make up these powerful machines.

The power unit is the heart of any stone chain saw machine. It typically consists of a robust engine or electric motor that generates the necessary power to drive the saw chain. Most machines are equipped with either a gasoline engine or an electric motor, depending on the intended use and operational requirements. The choice of power unit affects the mobility, cutting speed, and overall efficiency of the machine. Gasoline engines provide higher mobility, making them suitable for outdoor quarrying, while electric motors are ideal for indoor operations due to lower emissions and noise levels.

The saw chain is a crucial component that directly impacts the machine's cutting effectiveness. Made from high-strength steel, the saw chain features sharp teeth designed to cut through various types of stone, including granite, marble, and sandstone. The design of the chain, including the spacing of the teeth and their sharpness, plays a significant role in determining the speed and quality of the cut. Regular maintenance, such as sharpening the teeth and checking for wear, is essential to ensure optimal performance and longevity of the chain.

The guide bar serves as the framework for the saw chain, providing stability and direction during the cutting process. It is typically constructed from durable materials to withstand the forces exerted during operation. The length of the guide bar can vary, allowing for different cutting depths and widths. Choosing the correct guide bar length is essential based on the specific stone being cut and the desired outcome. A well-maintained guide bar ensures smoother operation and reduces the risk of damaging the saw chain.

Cutting stone generates significant heat, which can lead to overheating and potential damage to the machine. The cooling system is designed to dissipate this heat, ensuring that the power unit and other components operate within safe temperature ranges. Most stone chain saw machines utilize a water-cooling system, where water is circulated around the cutting area. This not only cools the machine but also helps to reduce dust and debris during operation, resulting in a cleaner work environment and improved visibility for the operator.

The control system is the interface through which the operator manages the machine's functions. It includes various controls for starting and stopping the machine, adjusting cutting speeds, and engaging or disengaging the saw chain. Modern machines often feature advanced electronic controls that enhance user experience and safety. A well-designed control system allows for precise handling and minimizes the risk of accidents, making it crucial for effective operation.

Safety is paramount when operating heavy machinery like stone chain saws. Manufacturers incorporate several safety features to protect the operator and surrounding personnel. Common safety features include emergency stop buttons, protective guards around moving parts, and safety switches that prevent accidental starts. Proper training and adherence to safety protocols are also essential to ensure safe operation. Regular inspections of safety mechanisms help maintain their effectiveness and reliability.

The frame and chassis of a stone chain saw machine provide structural integrity and support for all other components. Constructed from high-strength materials, the frame must withstand the vibrations and stresses associated with cutting hard stone. A well-designed chassis contributes to the machine's stability during operation, reducing the likelihood of tipping or misalignment. Additionally, a compact and ergonomic design enhances maneuverability, especially in tight spaces within quarries or workshops.

Many stone chain saw machines come with a variety of accessories and attachments that enhance their versatility. These may include different types of saw chains for various cutting applications, extension bars for deeper cuts, and specialized guides for intricate work. Choosing the right accessories based on the specific tasks at hand can significantly improve productivity and the quality of the finished product. Users should also consider the compatibility of attachments with their specific machine model.

Understanding the main components of a stone chain saw machine is vital for anyone involved in stone processing and quarrying. Each component plays a critical role in the overall performance, safety, and efficiency of the machine. From the power unit and saw chain to the control system and safety features, every element contributes to the machine's ability to cut stone accurately and efficiently. By maintaining these components and utilizing the right practices, operators can enhance productivity and ensure the longevity of their equipment. In conclusion, investing time in understanding and caring for these machines will result in better outcomes and safer working environments.