Author:Huada Quarrying Machine FROM:Stone quarry machine manufacturer TIME:2025-01-08

Rock mining machines play a crucial role in the extraction of minerals and resources from the earth. These powerful machines are designed to break up hard rock formations, making it easier for miners to access valuable materials such as gold, copper, and coal. The evolution of rock mining technology has significantly enhanced productivity and safety in the mining industry. This article explores the different types of rock mining machines, their functions, advancements, and the importance of these machines in modern mining operations.

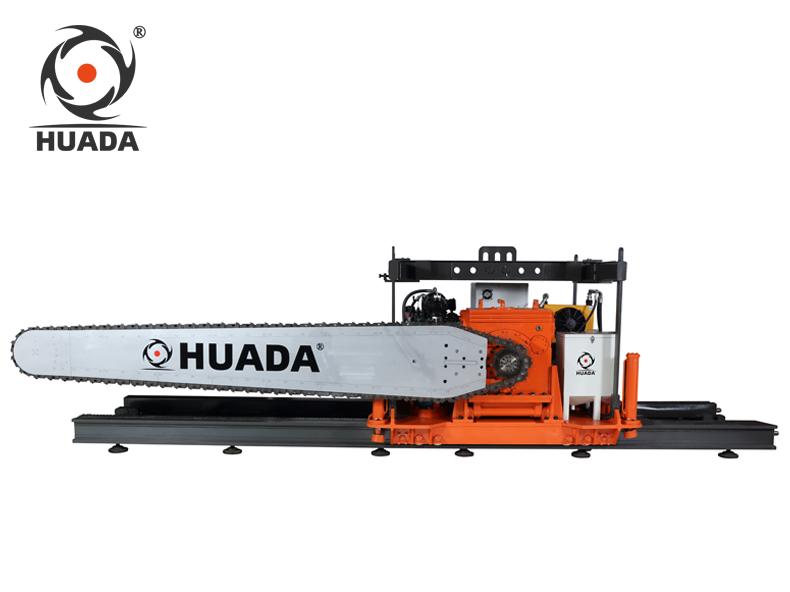

There are several types of rock mining machines, each designed for specific tasks within the mining process. The most commonly used machines include drillers, crushers, and excavators. Drillers are used to create holes in the rock, allowing explosives to be inserted for blasting. Crushers, on the other hand, break down larger rock fragments into smaller pieces, making them easier to transport and process. Excavators are essential for removing broken rock and debris, ensuring that the mining operation continues smoothly.

Drilling machines are fundamental in the rock mining process. These machines come in various forms, including rotary drills, percussive drills, and diamond drills. Rotary drills use a rotating drill bit to penetrate hard rock, while percussive drills utilize a hammering action to break through the surface. Diamond drills are particularly effective for accessing deeper mineral deposits due to their ability to cut through tough materials. The advancement of drilling technology has led to more efficient and precise drilling operations, reducing time and labor costs in the mining sector.

Once the rock has been blasted, crushing machines take over to break down the larger pieces into manageable sizes. There are several types of crushers used in mining, including jaw crushers, cone crushers, and impact crushers. Jaw crushers are excellent for primary crushing, handling large rocks with ease. Cone crushers are used for secondary and tertiary crushing, providing finer material sizes. Impact crushers offer versatility in processing different rock types, using high-speed impact to fracture the material. The effectiveness of these machines not only facilitates easier handling of materials but also enhances the overall efficiency of the mining operation.

Excavation equipment is vital for removing broken rock and debris after the crushing process. Large excavators are commonly employed in mining operations, equipped with powerful buckets designed for heavy lifting. These machines can dig deep into the ground, allowing miners to access mineral deposits located below the surface. Additionally, loaders and dump trucks are often used to transport the excavated materials to processing facilities. The combination of these machines ensures a continuous flow of operations, maximizing productivity in the mining industry.

The mining industry has seen significant technological advancements in rock mining machines over the years. Automation and remote-controlled machinery have improved safety and efficiency, reducing the need for human intervention in hazardous environments. GPS and real-time data analytics have enabled better planning and execution of mining operations, allowing for precise targeting of mineral deposits. Innovations such as electric and hybrid-powered machines are also gaining traction, promoting environmentally friendly practices in mining. These advancements not only enhance productivity but also contribute to sustainable mining practices.

Safety is paramount in the mining industry, and the use of advanced rock mining machines plays a significant role in minimizing risks. Modern machines are equipped with safety features such as emergency shut-off controls, rollover protection systems, and enhanced visibility for operators. Training and certification programs for machine operators ensure that personnel are well-equipped to handle the machinery safely. By prioritizing safety measures, mining companies can protect their workforce while maintaining high levels of productivity.

The environmental impact of rock mining is a growing concern, prompting the industry to adopt more sustainable practices. The use of efficient rock mining machines reduces waste and minimizes land disturbance. Additionally, advancements in technology have led to the development of machines that consume less energy and produce fewer emissions. Companies are increasingly implementing measures to reclaim and restore mining sites post-extraction, further mitigating environmental damage. By focusing on sustainability, the mining industry can continue to meet global resource demands while protecting the planet.

In conclusion, rock mining machines are indispensable tools that enable efficient mineral extraction while enhancing safety and productivity. From drilling to crushing and excavation, these machines have transformed the mining industry, allowing for more effective resource management. As technology continues to evolve, the future of rock mining will likely see even greater advancements, prioritizing both efficiency and environmental responsibility. Understanding the critical role these machines play helps us appreciate the complexities of mining and its significance in our everyday lives.