Author:Huada Quarrying Machine FROM:Stone quarry machine manufacturer TIME:2025-01-06

A stone chainsaw machine is a powerful tool designed for cutting and shaping various types of stone. Unlike traditional chainsaws, which are primarily used for wood, stone chainsaw machines utilize specialized diamond-tipped blades to effectively cut through hard materials such as granite, marble, and limestone. This article will delve into the workings of a stone chainsaw machine, exploring its components, mechanisms, and applications in the stone industry.

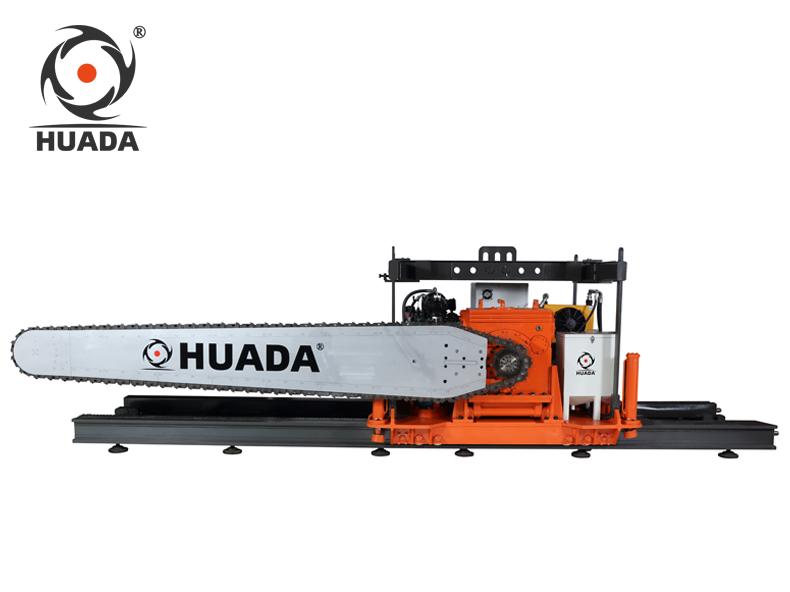

The stone chainsaw machine consists of several critical components that work together to achieve precise cutting. The primary elements include the cutting head, the chain, the motor, and the frame. The cutting head houses the diamond-tipped blade, which is specifically designed for stone cutting. The chain, similar to that of a regular chainsaw, moves around this cutting head, allowing for continuous cutting motion.

The motor powers the machine, typically using either electric or hydraulic systems. Electric motors are ideal for smaller jobs, while hydraulic motors are more suitable for heavy-duty tasks. The frame provides structural integrity and stability, ensuring that the machine can withstand the rigorous demands of stone cutting.

The cutting mechanism of a stone chainsaw machine revolves around the movement of the chain and the rotation of the cutting head. When the machine is powered on, the motor activates the chain, causing it to spin rapidly around the cutting head. The diamond-tipped teeth on the chain penetrate the stone, allowing for smooth and efficient cutting.

This process relies heavily on the design of the blade and the type of diamonds used. High-quality diamonds are essential for durability and effectiveness, enabling the machine to cut through even the hardest stones with precision. The speed and pressure applied during cutting can also be adjusted, ensuring optimal performance based on the specific type of stone being worked on.

One of the critical aspects of operating a stone chainsaw machine is the cooling and lubrication system. Cutting through stone generates significant heat, which can damage both the blade and the machine itself. To mitigate this, most stone chainsaw machines are equipped with water-cooling systems that continuously supply water to the cutting area.

This water not only cools the blade but also helps to reduce dust and debris generated during cutting. Additionally, some machines may incorporate lubricants to ensure the chain operates smoothly, further extending the lifespan of the tool. Proper maintenance of these systems is crucial for the longevity and efficiency of the machine.

Stone chainsaw machines are versatile and find applications in various industries. They are primarily used in quarrying, where large blocks of stone need to be extracted and shaped. The precision of these machines allows for intricate designs and clean cuts, making them ideal for producing tiles, slabs, and sculptures.

In construction, stone chainsaws are utilized for creating openings in walls, cutting countertops, and shaping stone features for landscaping. Their ability to cut through tough materials quickly makes them an invaluable asset on job sites. Additionally, artisans and craftsmen use these machines for detailed work, allowing them to create unique stone pieces that require meticulous attention to detail.

The use of a stone chainsaw machine offers numerous advantages over traditional cutting methods. Firstly, the efficiency of these machines significantly reduces cutting time, enabling workers to complete projects faster. Secondly, the precision provided by the diamond-tipped blades results in cleaner cuts, minimizing the need for extensive finishing work.

Moreover, stone chainsaws produce less waste compared to other cutting techniques. The ability to adjust cutting speeds and pressures means that operators can optimize their approach based on the specific stone type, leading to better material utilization. Lastly, the advancements in technology have made these machines more user-friendly and safer to operate, with enhanced safety features and controls.

While stone chainsaw machines offer many benefits, safety is paramount when operating such powerful equipment. Operators should always wear personal protective equipment (PPE), including goggles, gloves, and ear protection. Additionally, understanding the machine's functionality and adhering to operational guidelines is crucial to prevent accidents.

Regular maintenance checks are also necessary to ensure the machine is in good working condition. This includes inspecting the blade for wear and tear, checking the cooling system, and ensuring that all safety features are functioning correctly. Training and experience play vital roles in operating stone chainsaw machines safely and effectively.

In summary, a stone chainsaw machine is an essential tool in the stone industry, offering efficiency, precision, and versatility. Understanding its components, how it operates, and its applications can greatly enhance productivity and quality in stone cutting. By prioritizing safety and maintenance, operators can maximize the benefits of these machines while minimizing risks. As technology continues to advance, we can expect further innovations in stone cutting machinery that will make the process even more efficient and effective.