Author:Huada Quarrying Machine FROM:Stone quarry machine manufacturer TIME:2024-12-29

Choosing the right stone chain saw machine can significantly impact your efficiency and effectiveness in stone quarrying and processing. With various options available on the market, it’s crucial to understand your specific needs and how different machines can meet them. In this article, we will explore key factors to consider when selecting a stone chain saw machine, including types, features, and maintenance requirements.

Before diving into the selection process, it's essential to assess your specific needs. Consider the type of stone you will be cutting, the scale of your operations, and the environment in which you will be working. For instance, if you are working with hard granite, you'll need a machine designed to handle high-density materials. Conversely, softer stones may require less robust machinery. Additionally, think about the volume of stone you expect to cut and whether you need a portable or stationary machine.

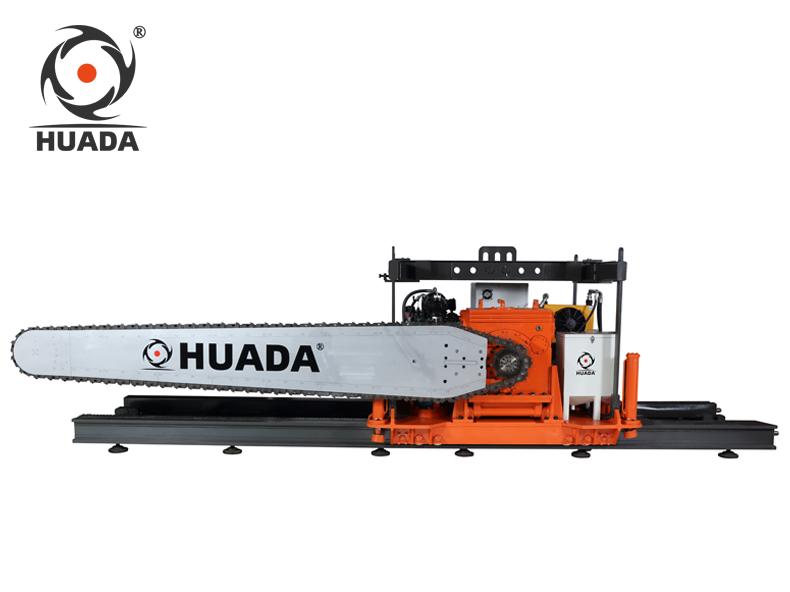

There are several types of stone chain saw machines available, each suited for different applications. The most common types include handheld saws, rail saws, and stationary saws. Handheld saws offer flexibility and are ideal for smaller projects or intricate cuts. Rail saws are more suitable for larger operations, providing greater stability and precision for extensive cuts. Stationary saws are best for high-capacity needs, allowing for continuous operation in a controlled setting. Understanding these types will help you determine which is the best fit for your work environment.

When evaluating stone chain saw machines, certain features can enhance performance and usability. Look for machines with adjustable cutting depths, which allow for versatility in various applications. Additionally, consider the weight and portability of the machine, especially if you need to transport it frequently. A machine with ergonomic design can reduce fatigue during long work hours. Furthermore, examine the power source—electric, diesel, or hydraulic—and choose one that aligns with your operational capabilities and preferences.

The blade quality is paramount when selecting a stone chain saw machine. Higher-quality blades typically offer better durability and cutting efficiency. Check for compatibility with various types of blades, as this flexibility can extend the machine's usefulness across multiple projects. It’s also advisable to consider the availability of replacement blades and accessories, ensuring you can maintain optimal performance without extensive downtime.

Regular maintenance is crucial for the longevity and performance of your stone chain saw machine. Investigate the manufacturer's recommendations for maintenance schedules and procedures. Some machines may require more frequent maintenance than others. Additionally, consider the availability of customer support and technical assistance from the manufacturer. A reliable support system can save you time and resources in case of breakdowns or operational inquiries.

Budget is an important factor when selecting a stone chain saw machine. Prices can vary widely based on the machine's type, features, and brand. It's essential to balance cost with quality and functionality. Investing in a slightly more expensive machine with better features may save you money in the long run through improved efficiency and reduced maintenance costs. Always compare prices among different suppliers and look for warranties or service packages that offer additional value.

Before making a final decision, research user reviews and seek recommendations from industry professionals. Genuine feedback can provide insights into the machine's performance, reliability, and ease of use. Online forums, trade shows, and industry publications often have valuable information that can aid in your decision-making process. Engaging with other users can also highlight potential pitfalls or advantages you may not have considered.

Choosing the right stone chain saw machine requires careful consideration of your specific needs, the types of machines available, and key features that enhance performance. By understanding your operational requirements, evaluating the various options, and consulting with experts, you can make an informed decision that will contribute to your success in stone cutting and processing. Take the time to assess your options thoroughly, and you will find a machine that meets your needs and supports your business objectives effectively.